I. Core Obstacles to the Popularization of High-Efficiency and Energy-Saving Motors

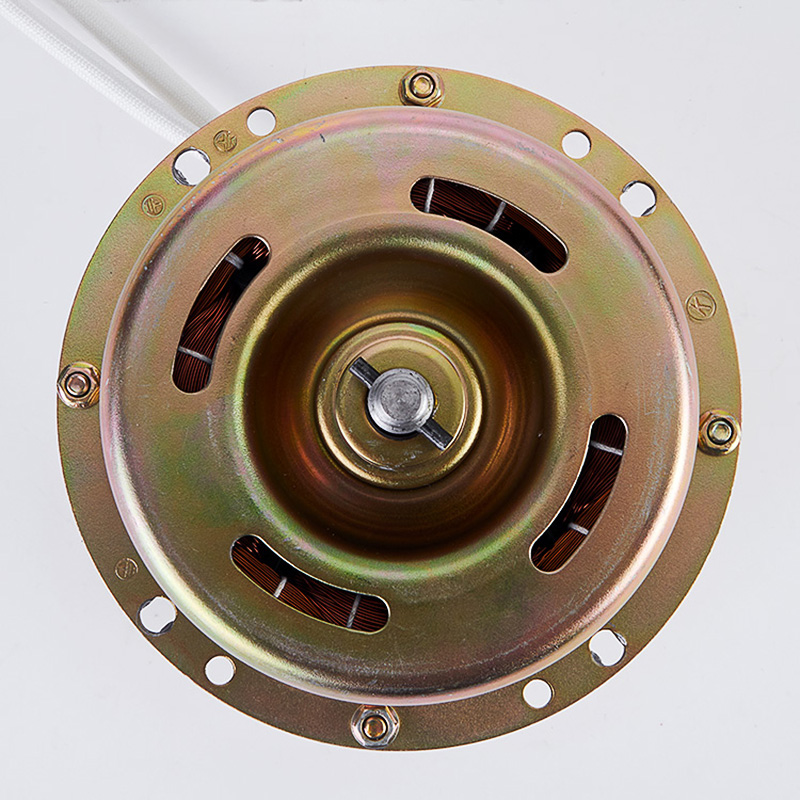

By optimizing electromagnetic design, adopting new materials (such as rare earth permanent magnets) and precision manufacturing processes, high-efficiency and energy-saving motors have an energy efficiency improvement of 5%-15% compared with ordinary motors. In industrial scenarios, an 11kW high-efficiency motor can save more than 10,000 yuan in electricity fees per year. However, its popularization rate is less than 40%, and the core obstacles are concentrated in three aspects.

The first is the contradiction between initial cost and investment return. The manufacturing cost of high-efficiency and energy-saving motors is 20%-50% higher than that of ordinary motors. For example, the unit price of an ordinary 30kW asynchronous motor is about 3,000 yuan, while the high-efficiency permanent magnet synchronous motor costs 4,500-6,000 yuan. For small and medium-sized enterprises, especially those in industries with meager profits such as textiles and hardware, short-term capital pressure has become the primary concern. Some enterprises are more inclined to choose low-cost ordinary motors and ignore long-term energy-saving benefits.

The second is the issue of adaptability and transformation thresholds. Most old production equipment is “customized to match” traditional motors. When replacing with high-efficiency motors, it is necessary to simultaneously transform the transmission system, control system, and even adjust the production line. Taking pump equipment in the chemical industry as an example, after replacing with high-efficiency motors, it is necessary to recalibrate the matching degree between speed and load, and the transformation period of a single piece of equipment is about 3-7 days. This makes enterprises unwilling to upgrade due to concerns about shutdown losses. In addition, there is a lack of special high-efficiency motor models for some special scenarios (such as high-temperature and high-dust environments), which further restricts promotion.

The third is cognitive bias and lack of market regulation. On the one hand, many small and micro enterprises have an unclear understanding of the energy-saving benefits of high-efficiency motors and hold the misunderstanding that “energy saving does not save money”. On the other hand, there are “fake high-efficiency” products on the market. Some merchants mislead consumers by falsely marking energy efficiency levels, damaging market trust. At the same time, the supervision of the implementation of energy efficiency standards is insufficient, leading to the continued circulation of low-energy-efficiency motors.

II. Solutions to Break Through the Popularization Bottlenecks

To address the above obstacles, it is necessary to build a trinity system of “policy guidance + technological innovation + market regulation” to promote the comprehensive popularization of high-efficiency and energy-saving motors.

In terms of policy and financial support, efforts should be made to increase targeted subsidies, tilting them towards small and medium-sized enterprises. For example, a purchase subsidy of 200-500 yuan per kilowatt can be provided based on motor power, and low-interest loans can be offered to support transformation projects. At the same time, an “old-for-new” mechanism should be established to provide additional rewards to enterprises that eliminate high-energy-consuming motors, reducing replacement costs. Some regions have piloted the inclusion of high-efficiency motor promotion in the carbon trading system, allowing enterprises to convert energy-saving benefits into carbon assets and enhancing promotion momentum.

In terms of technological adaptability and innovation, enterprises need to launch “customized solutions”, develop high-efficiency motors with strong compatibility for old equipment, and simplify the transformation process. For example, motors with modular design can directly replace the original models without large-scale equipment adjustments. At the same time, research and development of motors for special scenarios should be strengthened, such as high-temperature-resistant high-efficiency motors for mining machinery and anti-corrosion high-efficiency motors for marine engineering, to fill market gaps. In addition, intelligent high-efficiency motors should be developed by combining the Internet of Things technology. By monitoring energy consumption data in real time, accurate energy-saving analysis can be provided for enterprises, enhancing the attractiveness of products.

In terms of market regulation and cognitive improvement, the energy efficiency standard system should be improved, further raising the energy efficiency threshold of high-efficiency motors from the current GB18613-2020 standard. At the same time, quality supervision should be strengthened to severely crack down on false marking. In addition, activities such as “energy-saving diagnosis entering enterprises” should be carried out, and professional institutions should be organized to calculate energy-saving benefits for enterprises free of charge. For example, through the simple formula of “motor power × operation time × electricity price × energy efficiency improvement rate”, enterprises can intuitively understand the payback period (usually 1-3 years for high-efficiency motors). Industry associations can establish a high-efficiency motor certification platform to endorse high-quality products and guide benign market competition.

III. Conclusion

The popularization of high-efficiency and energy-saving motors is not a simple product replacement issue, but a systematic project involving costs, technology, and the market. With the precision of policy support, the implementation of technological innovation, and the standardization of the market environment, obstacles such as high initial investment and poor adaptability will be gradually overcome. As the “energy-saving core” in the industrial field, the comprehensive popularization of high-efficiency and energy-saving motors can not only reduce the operating costs of enterprises but also provide solid support for the realization of the “dual carbon” goals, becoming a key driver for the green transformation of industry.