In industrial production scenarios, from large machine tools to heavy-duty compressors, the popularity of three-phase AC motors far exceeds that of single-phase AC motors. This phenomenon is not accidental; it is determined by the inherent differences between the two in three core dimensions: structural design, operating performance, and energy efficiency. The specific reasons can be analyzed from the following four aspects:

1. Differences in Rotating Magnetic Field Generation Efficiency

The stator windings of three-phase AC motors adopt a symmetrical three-phase distributed design. When three-phase AC power with a phase difference of 120° is applied, a continuous rotating magnetic field is directly formed inside the motor, enabling smooth startup without additional starting devices. In contrast, single-phase AC motors can only generate a “pulsating magnetic field” and require phase difference creation through capacitor phase splitting or shaded-pole structures to start. This not only increases circuit complexity but also results in a starting torque that is only 1/3 to 1/2 of that of three-phase motors, failing to meet the heavy-load starting requirements of industrial equipment.

2. Advantages in Operational Stability and Power Density

The electromagnetic torque of three-phase motors is driven by three-phase currents, leading to minimal torque fluctuation (with a fluctuation coefficient typically <5%). Consequently, their operating vibration and noise are significantly lower than those of single-phase motors (whose torque fluctuation coefficient can reach 20%-30%)—a critical factor for high-precision processing equipment such as CNC machine tools. Meanwhile, for the same volume, the rated power of three-phase motors can be 3 to 5 times that of single-phase motors. For example, a 10kW three-phase motor has a volume equivalent to that of a 3kW single-phase motor, making it more suitable for the “small volume, high power” demands of industrial scenarios.

3. Energy Efficiency and Grid Compatibility

In terms of energy efficiency, the power factor of three-phase motors (usually 0.85-0.95) is much higher than that of single-phase motors (0.6-0.75). Under the same output power, three-phase motors reduce electrical energy loss by 20%-30%, meeting industrial energy-saving requirements. Regarding grid adaptability, industrial power grids generally adopt three-phase power supply systems. If single-phase motors operate at high power for extended periods, they easily cause three-phase load imbalance and trigger grid voltage fluctuations. In contrast, three-phase motors can evenly distribute loads, ensuring grid stability.

4. Differences in Maintenance Costs and Service Life

The winding structure of three-phase motors is more symmetrical, with uniform current distribution and low risk of local overheating, resulting in an average service life of 10-15 years. For single-phase motors, frequent switching between the starting winding and running winding causes easy contact wear, and vulnerable components such as capacitors require regular replacement. Their annual maintenance cost is approximately 2-3 times that of three-phase motors, leading to poor long-term economic efficiency.

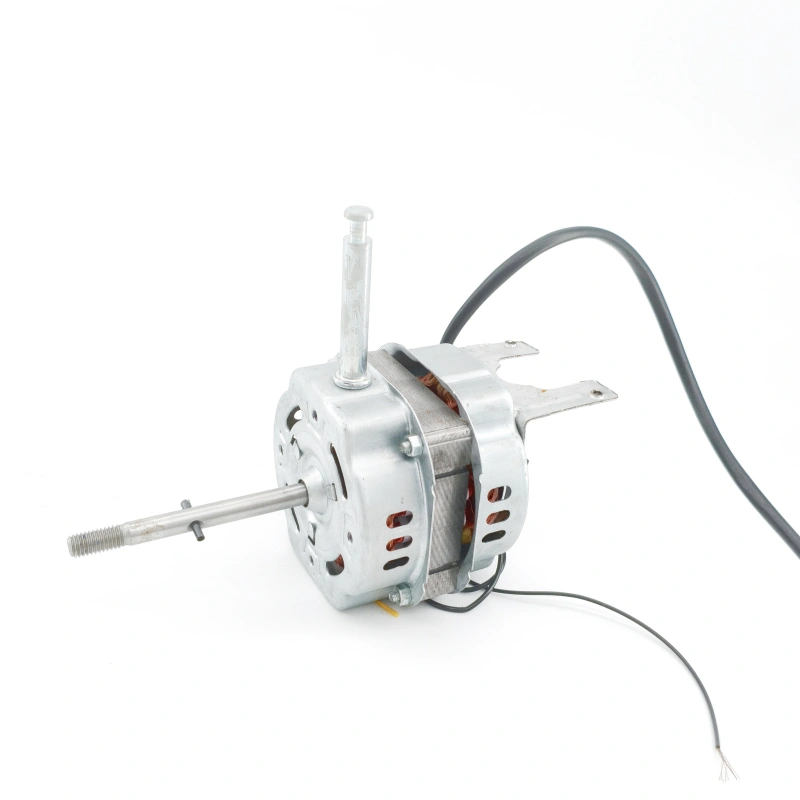

In summary, the comprehensive advantages of three-phase AC motors in starting performance, operational stability, energy efficiency, and maintenance costs make them the first choice in industrial fields. In contrast, single-phase AC motors, limited by power constraints and insufficient stability, are more suitable for low-power civilian scenarios such as household fans and small water pumps.