In daily use, many people encounter the situation where the noise of a fan suddenly increases after being used for a period of time. This not only affects concentration during rest and work but also makes people worry about potential safety hazards of the fan. In fact, the increase in fan noise is not without warning; it is mostly related to component wear, improper installation, or usage environment. As long as the cause is identified, the problem can be effectively alleviated through simple operations.

From the perspective of common causes, the first thing to consider is dust accumulation and deformation of fan blades. After long-term use of the fan, dust and hair in the air will adhere to the surface of the fan blades, especially the edges and back of the blades, resulting in uneven weight distribution of the blades. When rotating, the offset center of gravity causes the blades to “shake”, which then rubs against the air and produces a “buzzing” sound. The higher the rotation speed, the more obvious the noise. If the fan has been collided or dropped, the blades may be slightly bent or deformed, which not only destroys the aerodynamic design but also may rub against the fan housing when rotating, producing a harsh “scratching sound”.

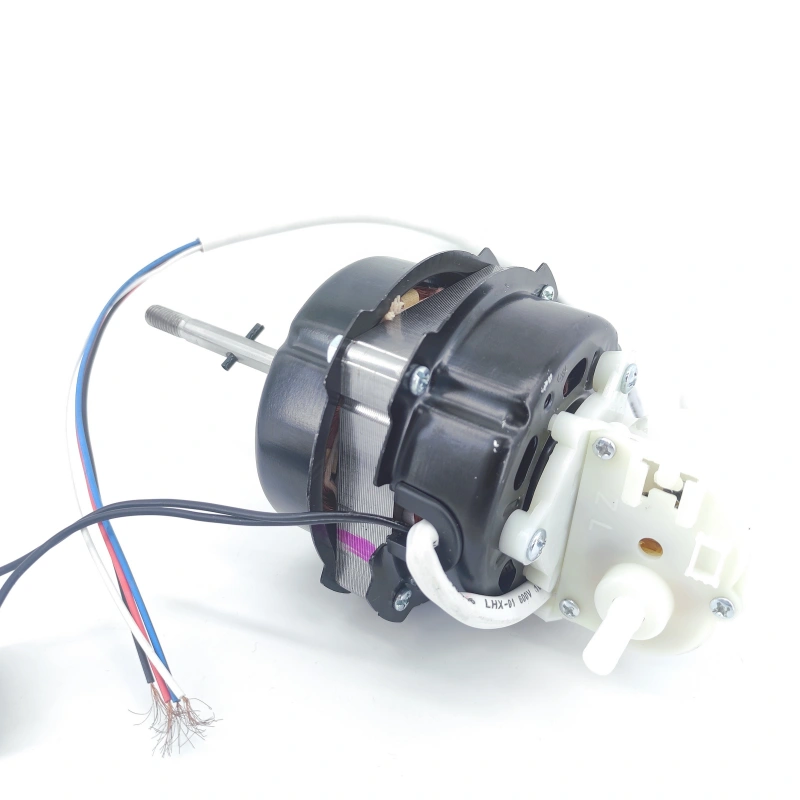

The second cause is motor aging and lack of oil. The motor is the “heart” of the fan, and the internal bearings (ball bearings or sleeve bearings) will gradually wear out during long-term high-speed rotation. For sleeve bearing motors, the lubricating oil will volatilize and dry up over time, increasing the frictional resistance between the bearings, and a “squeaking” or “clunking” friction sound will be produced when rotating. For ball bearing motors, if dust enters, the wear between the balls and the raceway will be aggravated, and the noise will also increase accordingly. In addition, if the motor windings are aged and the number of turns is loose, abnormal electromagnetic noise will be generated when the motor is running. This kind of noise is usually a low “buzzing sound” accompanied by obvious heating of the motor.

The third cause is loose installation and improper placement. During the assembly of the fan, if the connecting screws between the fan blades and the motor shaft are loose, the fan blades will be “eccentric” when rotating, colliding with the motor housing or protective net and generating noise. For floor fans, insufficient counterweight of the base, loose bracket screws, or uneven placement of table fans on the desktop will cause the entire fan to shake when running, and the base will collide with the ground or desktop, producing a “tapping” sound. For some wall-mounted fans, if the expansion screws are not fixed firmly during installation, the fan body will drive the wall to vibrate slightly when rotating, and the noise will be amplified through the wall transmission.

The last cause is issues with the usage environment and function settings. If there are soft objects such as curtains and clothes around the fan, the air flow will be blocked and disturbed by these objects when the fan rotates, forming irregular “airflow noise”, which is more obvious especially at high speed gears. For some fans with an oscillating function, wear and jamming of the gears in the oscillating mechanism will cause a “clicking” sound when oscillating. In addition, if the fan is in a humid environment for a long time, the motor or bearings may rust, which will also increase the rotation resistance and lead to increased noise.

To address the above causes, the problem can be solved by following the steps of “first clean, then inspect, and finally maintain”:

- Clean the fan blades and protective net: First, unplug the fan power, remove the protective net, and wipe the fan blades with a soft brush or a cloth dipped in neutral detergent (be careful with the strength to avoid blade deformation). Pay special attention to cleaning the dust on the edges and back of the fan blades. After cleaning, dry them and reinstall. This can solve the noise caused by the offset center of gravity due to dust accumulation.

- Inspect and repair the fan blades: If the fan blades are slightly deformed, you can gently bend them back to their original position by hand after cutting off the power (ensure the blades are symmetrical). If the fan blades have cracks or severe deformation, it is recommended to replace them with blades of the same model to avoid motor overload caused by blade problems.

- Maintain the motor and bearings: For sleeve bearing motors, 2-3 drops of special lubricating oil can be dripped into the oil injection holes at both ends of the motor (avoid using edible oil, which is easy to absorb dust). For ball bearing motors, if the noise is too loud, it is necessary to disassemble the motor housing, clean the dust in the bearings, and then apply grease. If the bearings are severely worn, new bearings need to be replaced. If the motor windings are aged, it is recommended to replace the motor directly (the winding repair is difficult, and the stability after repair is poor).

- Reinforce the installation and adjust the placement: Check the connecting screws between the fan blades and the motor shaft and tighten them with a screwdriver. For floor fans, ensure the base counterweight block is installed firmly and the bracket screws are not loose. Table fans should be placed on a flat desktop to avoid shaking. For wall-mounted fans, recheck the expansion screws to ensure the fan body is fixed stably.

- Optimize the usage environment: Keep the fan away from obstacles such as curtains and clothes to ensure smooth air flow. If the oscillating mechanism makes loud noise, a small amount of lubricating oil can be dripped into the gears. If the gears are jammed, it is necessary to clean the debris between the gears, and replace the oscillating mechanism if the problem is severe.

Through the above targeted treatments, most fan noise problems can be solved, which not only restores the quiet effect of the fan but also extends the service life of the fan. It should be noted that the power must be cut off throughout the operation process to avoid electric shock risks. If you are not familiar with the internal structure of the motor, it is recommended to contact professional maintenance personnel for handling to ensure safety.