DC motors are widely used in industrial equipment, household appliances and other scenarios. Stable speed is crucial to ensure the normal operation of equipment. If the speed fluctuates frequently by more than ±5%, it will lead to problems such as uneven feeding of conveyor belts and reduced precision of precision machining. A small machinery factory’s DC-driven lathe once experienced a drop in part processing qualification rate from 98% to 85% due to speed fluctuations. Therefore, quickly troubleshooting and resolving speed fluctuation issues is essential to ensure production efficiency and product quality.

I. Classification of Common Causes

The core causes of abnormal speed fluctuations in DC motors can be divided into three categories: power supply issues, motor self-faults, and control circuit abnormalities. In terms of power supply, unstable input voltage (such as sudden rises and drops in rural power grid voltage, or voltage fluctuations caused by shared lines of industrial equipment) or insufficient current supply will directly affect the electromagnetic torque of the motor armature winding, thereby causing speed fluctuations. Among motor self-faults, poor contact between the brush and commutator (such as brush wear, commutator surface oxidation), and partial short circuit or open circuit of the armature winding will disrupt the internal magnetic field balance of the motor, resulting in erratic speed. Abnormalities in the control circuit include incorrect governor parameter settings (such as improper proportional coefficient of the PID controller) and loss or delay of signals from feedback sensors (such as Hall sensors), which prevent accurate adjustment of motor speed.

II. Targeted Troubleshooting Methods

- Power Supply Troubleshooting

Use a multimeter to continuously monitor the voltage and current at the motor input terminal, and record the value changes during operation. If the voltage fluctuation range exceeds ±10% (for example, the voltage of a 24V rated motor fluctuates repeatedly between 21V and 27V), or the current is frequently lower than 80% of the rated value, it can be determined as a power supply problem. For instance, in a food processing factory, the DC conveyor belt motor was found to have a voltage fluctuation between 19V and 25V through testing, and the cause was diagnosed as unstable power supply due to the startup of high-power equipment in the workshop.

- Motor Self-Fault Troubleshooting

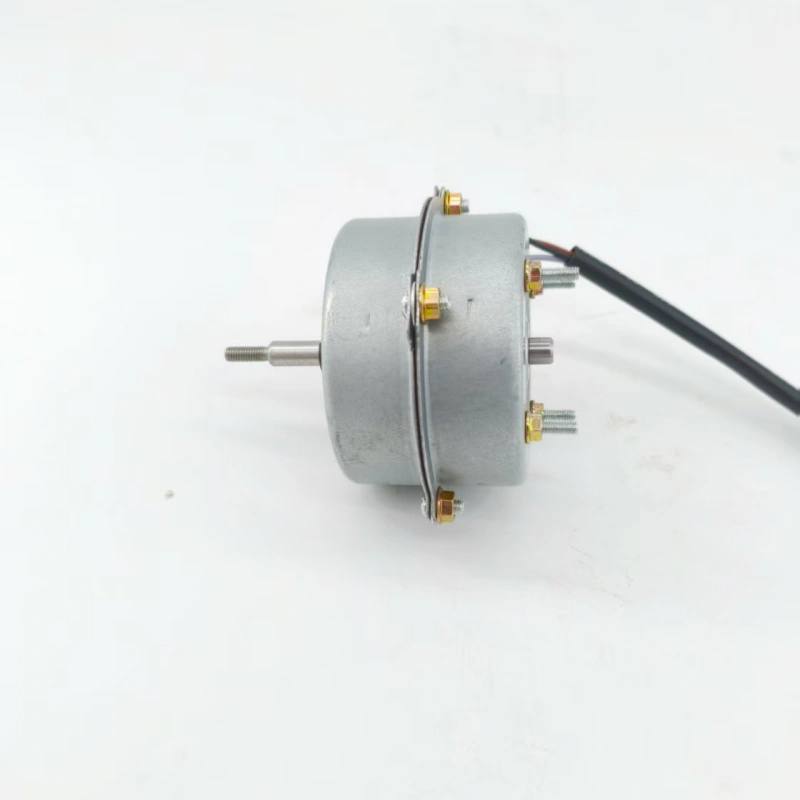

After powering off, remove the motor end cover, check the brush wear (replace if the brush length is less than 5mm), and observe whether the commutator surface has an oxide layer, scratches or carbon deposits (which can be gently polished and cleaned with fine sandpaper). Measure the insulation resistance of the armature winding with a megohmmeter; if the resistance value is lower than 0.5MΩ, there may be a winding short circuit. In a maintenance case, a DC fan motor had speed fluctuations due to severe carbon deposits on the commutator, and the fault disappeared after cleaning.

- Control Circuit Troubleshooting

Check the governor parameter settings and compare with the equipment manual to confirm whether the PID parameters (proportional P, integral I, derivative D) match the motor model. Use an oscilloscope to detect the output signal of the feedback sensor; if the signal is disconnected or has excessive noise, check whether the sensor wiring is loose or replace the sensor. In an automated equipment’s DC motor, the Hall sensor wiring was in poor contact, causing intermittent signals and frequent speed jumps. The problem was resolved after re-tightening the wiring.

III. Corresponding Solutions

- Solution for Power Supply Issues

If there is grid voltage fluctuation, install a DC voltage stabilization module (such as a 12-36V input, 24V output voltage stabilization module) to stabilize the motor input voltage. If the line current is insufficient, replace the wire with a larger cross-sectional area (such as replacing a 1.5mm² wire with a 2.5mm² wire) to reduce line loss. For a rural irrigation DC water pump, after installing a voltage stabilization module, the voltage was stabilized between 23.5V and 24.5V, and the speed fluctuation was reduced from ±8% to ±1.5%.

- Solution for Motor Self-Faults

Replace severely worn brushes (select carbon brushes matching the motor model) and clean the commutator surface with alcohol. If the armature winding is short-circuited, rewind the winding or replace the armature assembly. After replacing the brushes and cleaning the commutator of a DC motor, the speed fluctuation problem was completely solved, and the operating noise was also significantly reduced.

- Solution for Control Circuit Abnormalities

Re-calibrate the governor PID parameters according to the equipment manual. For example, adjust the proportional coefficient P from 5 to 3 and the integral time I from 100ms to 200ms to optimize the speed adjustment response. Replace the faulty feedback sensor to ensure stable signal transmission. After reconfiguring the governor parameters of a precision machine tool’s DC drive motor, the speed fluctuation was controlled within ±2%, and the machining accuracy was restored to the original level.

Through the above classified troubleshooting and targeted solutions, the problem of abnormal speed fluctuations in DC motors can be efficiently addressed, ensuring the stable operation of the motor, reducing equipment downtime due to faults, and improving production and operational efficiency.