AC motors and DC motors are two mainstream types of electrical drive equipment, with significant differences in structure, operating principles, and performance. Compared to DC motors, AC motors offer distinct advantages, which explain their wider adoption in industrial applications:

1. Structural and Cost Advantages

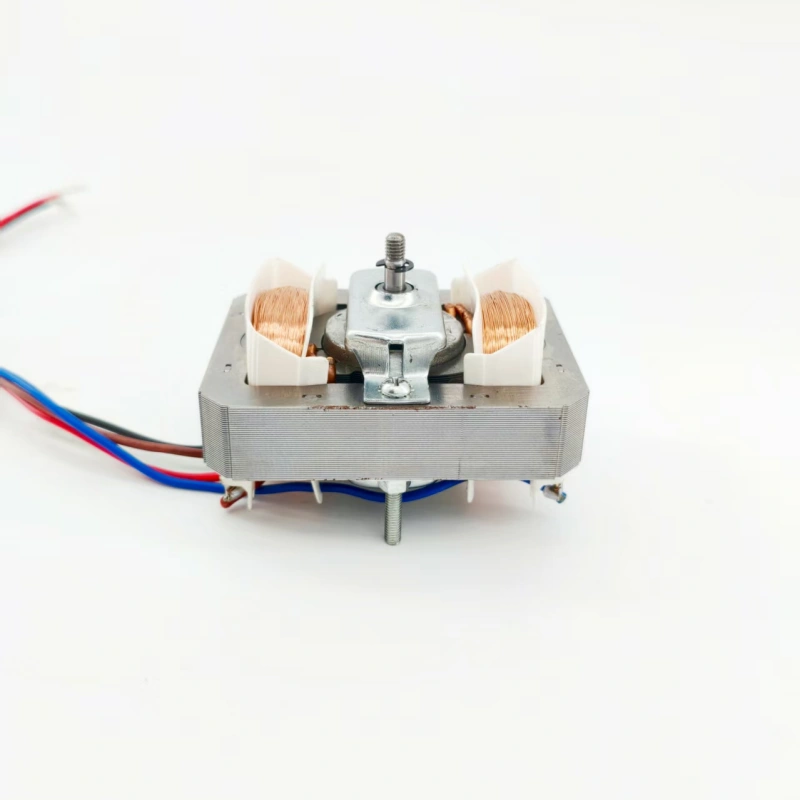

- Simpler Structure: An AC motor primarily consists of two main components: the stator and the rotor. The stator typically includes an iron core, windings, and end caps, while the rotor is composed of an iron core and windings. Its structure is relatively straightforward, lacking the complex mechanical commutation components (such as brushes and commutators) required by DC motors. DC motors rely on mechanical contact between brushes and commutators to reverse current direction, ensuring continuous torque output. This complex structure not only complicates the manufacturing process of DC motors but also increases potential points of failure.

- Lower Manufacturing Costs: Due to their simpler structure, AC motors require fewer raw materials and components, leading to lower manufacturing costs. For example, in mass production, the production costs of AC motors are easier to control, giving them a competitive edge in pricing. This aligns with the strict cost-control requirements of industrial applications. In contrast, DC motors have a more complex structure, demanding more materials like magnets and copper wires, and stricter manufacturing processes—all of which drive up their production costs.

2. Maintenance Cost Advantages

- Less Maintenance Work: AC motors have no 易损件 (wear-prone parts) like brushes or commutators, eliminating the need for regular replacement of these components. This significantly reduces maintenance workload—a critical benefit for industrial equipment that operates continuously for long periods. Less maintenance means less downtime and higher production efficiency. For DC motors, however, brushes and commutators wear out quickly during operation, requiring regular inspection, brush replacement, and commutator surface maintenance to ensure normal functioning. This not only consumes labor and resources but also risks motor failures and production delays if maintenance is delayed.

- Lower Maintenance Costs: Reduced maintenance workload translates to lower requirements for maintenance materials and specialized technicians, cutting overall maintenance costs. In industrial production, long-term equipment maintenance expenses are substantial, so the low maintenance cost of AC motors makes them more favored in industrial settings. DC motors, by contrast, incur higher operational costs and more downtime due to frequent maintenance and replacement of wear-prone parts, ultimately affecting a company’s economic efficiency.

3. Operational Performance Advantages

- Higher Efficiency: Traditionally, DC motors were thought to have higher energy conversion efficiency (over 90%), while AC motors typically operated at around 80%. However, with technological advancements—especially the development of new AC motor types like permanent magnet synchronous motors (PMSMs)—AC motor efficiency has improved significantly. Modern AC motors can deliver high power output with smaller size and lighter weight, boasting a power density approximately 20% higher than traditional DC motors. Moreover, AC motor efficiency remains relatively stable under different load conditions, making them suitable for equipment that runs continuously for long periods. In industrial settings, where many devices require stable long-term operation, this characteristic of AC motors better meets practical production needs.

- Easier Speed Regulation: In the past, DC motors had a unique advantage in speed control: smooth speed adjustment with a wide range could be achieved by regulating armature voltage or excitation current. However, the rapid development of power electronics has solved the speed regulation challenges of AC motors. Today, AC motor speed can be precisely controlled using devices like frequency converters, which adjust the frequency and voltage of the AC power supply. This speed regulation method not only offers a wide range and high precision but also delivers excellent dynamic performance, meeting diverse speed control needs in industrial production. Additionally, AC motor speed regulation systems are relatively simple and their costs are decreasing, further enhancing their competitiveness in industrial applications.

4. Reliability Advantages

- Reliability from No Mechanical Commutation: Without mechanical commutation components (brushes and commutators), AC motors avoid issues like sparks and wear caused by mechanical contact, reducing the probability of motor failures. This makes AC motors more reliable during operation and capable of stable performance in harsh working environments—such as high temperatures, high humidity, and dusty conditions—where their reliability advantages are even more pronounced. In contrast, the brushes and commutators of DC motors generate sparks during operation, which may cause electromagnetic interference and pose safety risks in flammable or explosive environments. Meanwhile, wear on brushes and commutators impairs motor performance and lifespan, lowering the reliability of DC motors.

- Reliability from Simple Structure: The simple structure of AC motors reduces stress and wear on individual components, extending the lifespan of parts and improving overall motor reliability. In industrial production, equipment reliability directly impacts production continuity and product quality. The high reliability of AC motors provides stable power support for industrial operations, minimizing production accidents and losses caused by motor failures.

5. Application Range Advantages

- High-Power Applications: AC motors can accommodate a wide power range, from small motors of several hundred watts to large motors of several megawatts. In industrial settings, many large-scale mechanical devices—such as blast furnace fans in steel plants, rotary kiln drive motors in cement plants, and hoists in mines—require high-power motors for operation, and AC motors can meet these high-power demands. DC motors, however, are limited by components like brushes and commutators, making it difficult to achieve high-power output. They are generally suitable for low-power applications.

- Large-Scale Industrial Production: AC motors have a high degree of standardization, facilitating mass production and batch manufacturing. Large-scale industrial production requires a large number of power devices, and the mass production capacity of AC motors can meet industrial demands for both quantity and quality. Additionally, AC motors have strong versatility: products from different manufacturers have certain compatibility in terms of performance and interfaces, making it easier to select, install, and replace equipment in industrial production.

In summary, AC motors outperform DC motors in structure and cost, maintenance costs, operational performance, reliability, and application range. These advantages have made AC motors the most widely used motor type in industrial settings. As technology continues to advance, the performance of AC motors will further improve, and their application prospects in industrial fields will become even broader.