Giới thiệu: Tầm quan trọng của vấn đề dòng khởi động quá mức

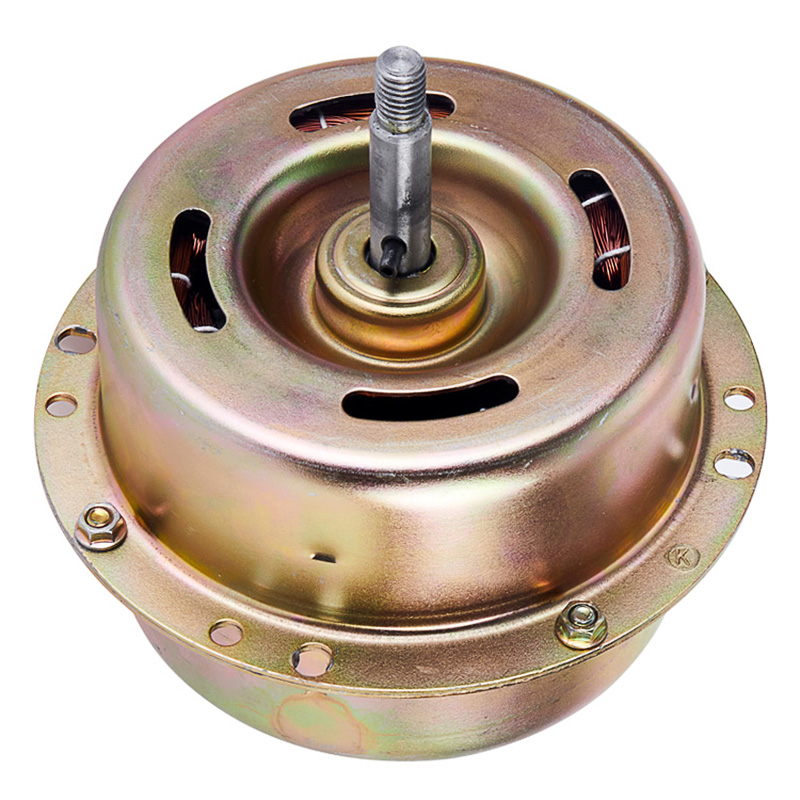

Là thiết bị điện cốt lõi trong các lĩnh vực như sản xuất công nghiệp và sử dụng điện dân dụng, hiệu suất khởi động của động cơ điện xoay chiều ảnh hưởng trực tiếp đến tuổi thọ thiết bị, sự ổn định lưới điện và hiệu quả sử dụng năng lượng. Trong các ứng dụng thực tế, dòng điện của động cơ điện xoay chiều trong quá trình khởi động thường cao hơn nhiều so với dòng điện định mức. Hiện tượng này không chỉ có thể gây quá nhiệt cuộn dây động cơ và làm lão hóa vật liệu cách điện mà còn dẫn đến dao động điện áp lưới, ảnh hưởng đến hoạt động bình thường của các thiết bị khác trong cùng lưới điện. Do đó, việc làm rõ nguyên nhân gây ra dòng điện khởi động quá mức ở động cơ điện xoay chiều và áp dụng các biện pháp khắc phục có mục tiêu là rất quan trọng trong thực tiễn kỹ thuật.

I. Phân tích các nguyên nhân gây ra dòng khởi động quá mức trong động cơ điện xoay chiều

Trước tiên, xuất phát từ nguyên lý cảm ứng điện từ và đặc điểm cấu tạo của động cơ, chúng ta phân tích các nguyên nhân cốt lõi gây ra dòng khởi động quá mức. Đối với động cơ AC không đồng bộ, tốc độ quay của rôto bằng 0 tại thời điểm khởi động. Sau khi cấp nguồn AC ba pha cho cuộn dây stato, tốc độ cắt tương đối giữa từ trường quay được tạo ra và dây dẫn rôto đạt giá trị cực đại. Theo định luật cảm ứng điện từ, một suất điện động cảm ứng rất mạnh được tạo ra trong dây dẫn rôto, từ đó tạo ra một dòng điện rôto rất lớn. Thông qua ghép nối điện từ, dòng điện rôto tác động lên cuộn dây stato, dẫn đến sự gia tăng đột ngột dòng điện stato. Thông thường, dòng khởi động có thể đạt gấp 5-8 lần dòng điện định mức. Ngoài ra, hệ số công suất của động cơ AC trong quá trình khởi động cực kỳ thấp, với một lượng lớn dòng điện được sử dụng để tạo ra từ trường, và tỷ lệ dòng điện được sử dụng cho công việc hiệu quả nhỏ, điều này càng làm trầm trọng thêm hiện tượng dòng điện quá mức. Đối với động cơ AC đồng bộ, mặc dù không có vấn đề trượt như động cơ không đồng bộ, nhưng cần phải khắc phục quán tính rôto để đạt được sự đồng bộ trong quá trình khởi động. Nếu khởi động trực tiếp, dòng điện cũng sẽ tăng đột biến do mô-men xoắn khởi động không đủ.

II. Nguy hiểm của dòng khởi động quá mức

Không thể bỏ qua những nguy hiểm do dòng khởi động quá mức gây ra. Một mặt, dòng điện quá mức sẽ tạo ra một lượng nhiệt Joule lớn trong cuộn dây động cơ. Nếu khởi động thường xuyên hoặc thời gian khởi động quá dài, nhiệt độ của cuộn dây sẽ vượt quá phạm vi cho phép, đẩy nhanh quá trình lão hóa vật liệu cách điện, rút ngắn tuổi thọ của động cơ, và thậm chí gây cháy cuộn dây trong trường hợp nghiêm trọng. Mặt khác, dòng điện lớn trong quá trình khởi động động cơ sẽ tạo ra sự sụt giảm điện áp lớn trên trở kháng của đường dây lưới điện, dẫn đến sự sụt giảm tức thời điện áp lưới. Đối với các thiết bị nhạy cảm với điện áp (như dụng cụ chính xác, máy tiện CNC, thiết bị chiếu sáng, v.v.), điều này có thể gây ra sự cố, suy giảm hiệu suất hoặc thậm chí tắt máy. Đồng thời, nó cũng sẽ làm giảm chất lượng cung cấp điện của lưới điện và ảnh hưởng đến hoạt động ổn định của lưới điện.

III. Các biện pháp kỹ thuật để hạn chế dòng khởi động quá mức

Để giải quyết các vấn đề nêu trên, một số biện pháp kỹ thuật phổ biến được sử dụng trong kỹ thuật để hạn chế dòng khởi động quá mức của động cơ điện xoay chiều:

(I) Phương pháp khởi nghiệp từng bước

Ý tưởng cốt lõi của phương pháp này là giảm sức điện động cảm ứng trong quá trình khởi động bằng cách hạ thấp điện áp cung cấp cho cuộn dây stato, từ đó giảm dòng điện khởi động. Các phương pháp khởi động hạ áp phổ biến bao gồm khởi động hạ áp sao-tam giác (Y-Δ), khởi động hạ áp bằng biến áp tự ngẫu, khởi động hạ áp bằng điện trở/điện kháng nối tiếp, v.v. Khởi động hạ áp sao-tam giác phù hợp với động cơ không đồng bộ sử dụng kết nối tam giác trong quá trình hoạt động bình thường. Trong quá trình khởi động, các cuộn dây stato được kết nối theo hình sao, giảm điện áp của mỗi cuộn dây pha xuống còn 1/√3 điện áp định mức, và dòng điện khởi động sau đó giảm xuống còn 1/3 so với khởi động trực tiếp. Phương pháp này có cấu trúc đơn giản và chi phí thấp, được sử dụng rộng rãi trong các động cơ không đồng bộ cỡ nhỏ và trung bình. Khởi động hạ áp bằng biến áp tự ngẫu điều chỉnh điện áp đầu ra thông qua các nấc của biến áp tự ngẫu, cho phép lựa chọn tỷ lệ hạ áp khác nhau theo yêu cầu khởi động, với phạm vi ứng dụng rộng hơn, nhưng thiết bị có kích thước lớn và chi phí tương đối cao. Khởi động giảm áp bằng điện trở/cuộn kháng làm giảm dòng điện stato bằng cách mắc thêm điện trở hoặc cuộn kháng vào mạch stato để tiêu thụ một phần điện áp. Tuy nhiên, khởi động bằng điện trở sẽ gây tổn thất năng lượng lớn và chủ yếu được sử dụng trong trường hợp yêu cầu khởi động thấp.

(II) Phương pháp khởi động mềm

Bộ khởi động mềm là một loại thiết bị khởi động mới dựa trên công nghệ điện tử công suất. Nó điều chỉnh điện áp cung cấp cho cuộn dây stato một cách mượt mà thông qua các thiết bị điện tử công suất bên trong như thyristor, cho phép tốc độ động cơ tăng dần từ 0 đến tốc độ định mức để đạt được quá trình khởi động êm ái. Bộ khởi động mềm có thể điều khiển chính xác dòng khởi động trong phạm vi 1,5-2,5 lần dòng định mức, tránh hiện tượng tăng giảm điện áp đột ngột. Đồng thời, nó có ưu điểm là mô-men xoắn khởi động có thể điều chỉnh và các chức năng bảo vệ đầy đủ (như bảo vệ quá dòng, bảo vệ quá nhiệt, bảo vệ mất pha, v.v.). Nó phù hợp cho các trường hợp yêu cầu cao về độ êm ái khi khởi động, chẳng hạn như máy bơm nước, quạt, băng tải và các thiết bị khác. So với các phương pháp khởi động giảm áp truyền thống, bộ khởi động mềm có tính thông minh cao hơn và có thể thực hiện điều khiển tự động, nhưng chi phí tương đối cao.

(III) Phương pháp khởi động tần số thay đổi

Khởi động bằng biến tần sử dụng bộ biến đổi tần số để chuyển đổi nguồn điện xoay chiều tần số công nghiệp thành nguồn điện xoay chiều có tần số và điện áp điều chỉnh được để cung cấp năng lượng cho động cơ. Trong quá trình khởi động, bộ biến tần xuất ra tần số và điện áp cực thấp, cho phép rôto động cơ tăng tốc chậm. Khi tốc độ tăng lên, tần số và điện áp đầu ra được tăng dần cho đến khi đạt giá trị định mức. Trong quá trình khởi động bằng biến tần, dòng điện khởi động của động cơ luôn được kiểm soát trong một phạm vi nhỏ, hầu như không ảnh hưởng đến lưới điện và động cơ. Đồng thời, nó có thể đạt được hoạt động tiết kiệm năng lượng, làm cho nó trở thành phương pháp khởi động tiên tiến và lý tưởng nhất hiện nay. Tuy nhiên, bộ biến tần có chi phí cao và yêu cầu vận hành và bảo trì chuyên nghiệp. Nó phù hợp với các động cơ xoay chiều lớn, thiết bị chính xác và các trường hợp có yêu cầu cao về tiết kiệm năng lượng và hiệu suất khởi động, chẳng hạn như máy nén khí lớn, thang máy, máy công cụ CNC, v.v.

IV. Tóm tắt và Triển vọng

Tóm lại, bản chất của dòng khởi động quá mức trong động cơ AC là hiệu ứng chồng chất của điều kiện cảm ứng điện từ và đặc tính hoạt động của động cơ tại thời điểm khởi động. Trong ứng dụng thực tế, cần phải lựa chọn hợp lý các biện pháp kỹ thuật như khởi động giảm áp, khởi động mềm hoặc khởi động biến tần dựa trên các yếu tố như công suất động cơ, môi trường hoạt động, tần số khởi động và điều kiện lưới điện để đạt được mục tiêu giảm dòng khởi động, bảo vệ thiết bị động cơ và ổn định hoạt động lưới điện. Với sự phát triển không ngừng của công nghệ điện tử công suất và công nghệ điều khiển tự động, công nghệ điều khiển khởi động động cơ AC sẽ phát triển theo hướng hiệu quả hơn, tiết kiệm năng lượng hơn và thông minh hơn, cung cấp nguồn điện đáng tin cậy hơn cho sản xuất công nghiệp và đời sống xã hội.