มอเตอร์ DC มีประโยชน์อะไรบ้าง?

มอเตอร์ DC ถูกใช้กันอย่างแพร่หลายในสถานการณ์ที่ต้องการการควบคุมความเร็วที่แม่นยำหรือแรงบิดเริ่มต้นสูง ครอบคลุมถึงอุตสาหกรรม การขนส่ง ครัวเรือน การแพทย์ และอุปกรณ์อิเล็กทรอนิกส์สำหรับผู้บริโภค เนื่องจากมอเตอร์เหล่านี้ ประสิทธิภาพการควบคุมความเร็วที่ยอดเยี่ยม แรงบิดเริ่มต้นสูง และการควบคุมที่เรียบง่ายข้อได้เปรียบหลักอยู่ที่การปรับความเร็วที่ราบรื่นและเสถียรผ่านการควบคุมแรงดันไฟฟ้าอาร์เมเจอร์หรือฟลักซ์แม่เหล็กเมื่อโหลดเปลี่ยนแปลง ซึ่งเป็นความสามารถที่มอเตอร์ AC หลายตัว (โดยเฉพาะมอเตอร์เหนี่ยวนำแบบดั้งเดิม) ประสบปัญหาในการทำให้เทียบเท่าได้ในราคาเดียวกัน

1. การผลิตภาคอุตสาหกรรม: แกนหลักของการขับเคลื่อนและระบบอัตโนมัติ

สถานการณ์ทางอุตสาหกรรมต้องการความน่าเชื่อถือสูง ความแม่นยำในการควบคุมความเร็ว และเสถียรภาพแรงบิดจากมอเตอร์ มอเตอร์กระแสตรง (โดยเฉพาะมอเตอร์กระแสตรงแบบแยกกระตุ้นและแบบชันท์-วาลด์) ทำหน้าที่เป็นส่วนประกอบขับเคลื่อนหลัก โดยมีการใช้งานทั่วไป ได้แก่:

1.1 อุปกรณ์เครื่องมือกล

- แกนหมุนหรือระบบป้อน สำหรับเครื่องมือตัดเฉือนแม่นยำ (เช่น เครื่องกลึง เครื่องกัด เครื่องเจียร): จำเป็นต้องปรับความเร็วตามวัสดุที่ใช้ในการผลิต (เช่น โลหะ พลาสติก) และกระบวนการ (การตัดเฉือนหยาบ/การตัดเฉือนละเอียด) ตัวอย่างเช่น เครื่องเจียรต้องการความเร็วต่ำและแรงบิดสูงเพื่อให้การเจียรมีความแม่นยำ มอเตอร์กระแสตรงช่วยให้สามารถควบคุมความเร็วแบบไม่มีขั้นตอนผ่านการควบคุม PWM เพื่อป้องกันข้อผิดพลาดในการตัดเฉือน

- ระบบเซอร์โวสำหรับเครื่องจักร CNC (Computer Numerical Control):เครื่อง CNC ระดับไฮเอนด์บางเครื่องยังคงใช้มอเตอร์เซอร์โว DC ซึ่งทำงานร่วมกับตัวเข้ารหัสเพื่อให้สามารถควบคุมตำแหน่งและความเร็วแบบวงปิดได้ ช่วยให้มั่นใจถึงความแม่นยำในการเคลื่อนที่ของเครื่องมือ

1.2 การลำเลียงและการยกวัสดุ

- สายพานลำเลียง:ความเร็วในการลำเลียงจะถูกปรับตามจังหวะการผลิต (เช่น กระบวนการต่างๆ ในสายการแปรรูปอาหารต้องการความเร็วที่แตกต่างกัน) มอเตอร์ DC มีช่วงความเร็วที่กว้าง สามารถตอบสนองความต้องการที่หลากหลายได้

- รอกไฟฟ้าและเครน: จำเป็นต้องมีแรงบิดเริ่มต้นสูงเพื่อเอาชนะแรงเสียดทานสถิตของภาระหนัก มอเตอร์กระแสตรงแบบพันรอบอนุกรม (ที่มีแรงบิดเริ่มต้นสูง) เหมาะสำหรับการสตาร์ทในระยะสั้นที่มีภาระหนัก (เช่น การยกของหนักในโรงงาน)

1.3 เครื่องจักรการพิมพ์และบรรจุภัณฑ์

- ลูกกลิ้งขับเคลื่อนสำหรับเครื่องพิมพ์:ความเร็วที่คงที่เป็นสิ่งสำคัญเพื่อให้แน่ใจว่าหมึกครอบคลุมสม่ำเสมอและหลีกเลี่ยงกราฟิกที่เบลอ มอเตอร์ DC มีความผันผวนของความเร็วขั้นต่ำและเปิดใช้งานการควบคุมความเร็วแบบซิงโครนัสผ่านการควบคุมแรงดันไฟฟ้าอาร์เมเจอร์

- เครื่องบรรจุภัณฑ์ (เช่น เครื่องปิดผนึก เครื่องติดฉลาก):ความเร็วการทำงานจะถูกปรับตามข้อกำหนดของบรรจุภัณฑ์ (เช่น ขนาดขวด ขนาดฉลาก) มอเตอร์ DC มีความเร็วในการตอบสนองที่รวดเร็ว ช่วยให้ปรับเปลี่ยนการผลิตได้อย่างรวดเร็ว

2. การขนส่ง: จากไดรฟ์เสริมไปยังแหล่งจ่ายไฟหลัก

ในการขนส่ง มอเตอร์ DC ใช้ประโยชน์จาก ความหนาแน่นแรงบิดสูง และ แรงบิดสูงที่ความเร็วต่ำ, มีการใช้ทั่วไปในยานพาหนะไฟฟ้าหรือระบบเสริม:

2.1 รถยนต์ไฟฟ้า (EVs/HEVs)

- มอเตอร์ขับเคลื่อนสำหรับ EV ในยุคแรกๆรถยนต์ไฟฟ้ารุ่นเก่าบางรุ่น (เช่น รถยนต์เทสลารุ่นแรกๆ บางรุ่น รถยนต์ไฟฟ้าความเร็วต่ำในจีน) เคยใช้มอเตอร์กระแสตรงแบบแยกส่วนเป็นมอเตอร์ขับเคลื่อน โดยควบคุมความเร็วของรถด้วยการปรับแรงดันไฟฟ้าของอาร์เมเจอร์ แม้ว่าปัจจุบันมอเตอร์เหล่านี้จะถูกแทนที่ด้วยมอเตอร์ซิงโครนัสแม่เหล็กถาวร (PMSM) ไปแล้วเป็นส่วนใหญ่ แต่มอเตอร์เหล่านี้ยังคงใช้กันอย่างแพร่หลายในรถยนต์ไฟฟ้าขนาดเล็ก (เช่น รถสามล้อไฟฟ้า สกู๊ตเตอร์ไฟฟ้าความเร็วต่ำ) เนื่องจากมีต้นทุนต่ำและควบคุมง่าย

- ระบบเสริมรถยนต์:ปั๊มพวงมาลัยพาวเวอร์และคอมเพรสเซอร์เครื่องปรับอากาศของยานยนต์ไฟฟ้าบางครั้งใช้มอเตอร์ DC ขนาดเล็ก (เช่น มอเตอร์ DC แม่เหล็กถาวร) ซึ่งมีขนาดกะทัดรัด ใช้พลังงานต่ำ และเข้ากันได้กับแหล่งจ่ายไฟ 12V/24V ของยานยนต์

2.2 การขนส่งทางรางและยานพาหนะพิเศษ

- ไดรฟ์เสริมสำหรับรถไฟใต้ดินและรถไฟฟ้ารางเบา:ระบบระบายอากาศและมอเตอร์ขับเคลื่อนประตูของรถไฟบางขบวนเป็นมอเตอร์ DC ซึ่งต้องมีการสตาร์ท/หยุดบ่อยครั้งและควบคุมความเร็วอย่างราบรื่นเพื่อป้องกันการติดขัดของประตู

- รถยกและ AGV (ยานพาหนะนำทางอัตโนมัติ):ในคลังสินค้า รถยกต้องการความเร็วต่ำและแรงบิดสูงในการยกสินค้า ในขณะที่ AGV ต้องการการควบคุมความเร็วที่แม่นยำเพื่อเคลื่อนที่ไปตามเส้นทาง ความยืดหยุ่นในการควบคุมของมอเตอร์กระแสตรง (โดยเฉพาะมอเตอร์กระแสตรงแม่เหล็กถาวร) ตอบโจทย์ความต้องการเหล่านี้

3. ครัวเรือนและชีวิตประจำวัน: การลดขนาดและการใช้พลังงานต่ำ

มอเตอร์ในสถานการณ์ครัวเรือนส่วนใหญ่ มอเตอร์กระแสตรงแม่เหล็กถาวรขนาดเล็ก (PMDC)มีลักษณะเด่นคือขนาดกะทัดรัด น้ำหนักเบา เสียงรบกวนต่ำ ใช้งานได้กับแหล่งจ่ายไฟฟ้าภายในบ้าน 220V (หลังการแก้ไข) หรือแบตเตอรี่

3.1 เครื่องใช้ในครัว

- เครื่องปั่นและเครื่องเตรียมอาหาร:ต้องปรับความเร็วตามความแข็งของส่วนผสม (เช่น ความเร็วสูงสำหรับการคั้นน้ำผลไม้ ความเร็วต่ำสำหรับการนวดแป้ง) มอเตอร์ DC ช่วยให้สามารถควบคุมความเร็วได้หลายระดับผ่าน PWM และมีแรงบิดเริ่มต้นสูงเพื่อป้องกันการติดขัดของส่วนผสม

- เครื่องชงกาแฟและเครื่องทำนมถั่วเหลือง:ปั๊มน้ำและส่วนประกอบในการบดมักใช้มอเตอร์ DC ขนาดเล็กเพื่อให้แน่ใจว่าการไหลของน้ำมีเสถียรภาพหรือการบดที่สม่ำเสมอ

3.2 อุปกรณ์ทำความสะอาดและดูแลขน

- เครื่องดูดฝุ่นมอเตอร์ DC แบบพันรอบต่อเนื่องทำงานด้วยความเร็วสูง (สูงสุดกว่า 10,000 รอบต่อนาที) ทำให้เกิดแรงดูดที่แรง แรงบิดของมอเตอร์สามารถปรับได้ตามการเปลี่ยนแปลงของภาระ (เช่น การดูดเศษวัสดุ) เพื่อป้องกันความเสียหายจากการโอเวอร์โหลด

- แปรงสีฟันไฟฟ้าและเครื่องโกนหนวดไฟฟ้า:ใช้มอเตอร์ไมโคร PMDC (มีเส้นผ่านศูนย์กลางเพียงไม่กี่มิลลิเมตร) ซึ่งมีความเร็วที่แม่นยำ (เช่น ความถี่การสั่นสะเทือนที่เสถียรสำหรับแปรงสีฟันไฟฟ้า) และแหล่งจ่ายไฟแรงดันต่ำ (แบตเตอรี่ลิเธียม 3.7V) เพื่อความปลอดภัยและความสะดวกในการพกพา

3.3 อุปกรณ์ในครัวเรือนอื่นๆ

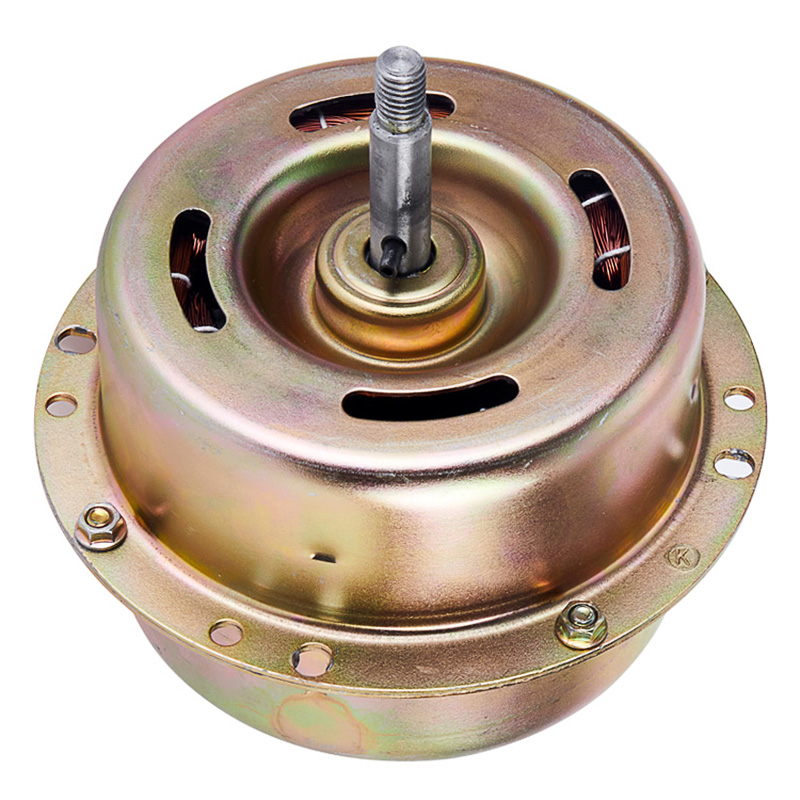

- พัดลมไฟฟ้าและเครื่องฟอกอากาศ:มอเตอร์ DC มีช่วงความเร็วที่กว้าง (ตั้งแต่ลมพัดเบาๆ จนถึงลมแรง) และใช้พลังงานน้อยกว่ามอเตอร์ AC แบบดั้งเดิมถึง 30% ตอบสนองความต้องการด้านการประหยัดพลังงาน

- ม่านไฟฟ้าและระบบล็อคประตูอัจฉริยะ:มอเตอร์ DC สตาร์ทและหยุดได้อย่างราบรื่นด้วยเสียงรบกวนต่ำ และสามารถควบคุมจากระยะไกลเพื่อปรับความเร็วหรือตำแหน่ง (เช่น ช่วงการเปิด/ปิดม่าน) ได้ด้วยตัวควบคุม

4. การวิจัยทางการแพทย์และวิทยาศาสตร์: ความแม่นยำและความน่าเชื่อถือสูง

สถานการณ์การวิจัยทางการแพทย์และวิทยาศาสตร์มีข้อกำหนดที่เข้มงวดสำหรับมอเตอร์ ความเสถียร ความปลอดเชื้อ (ในบางกรณี) และการควบคุมที่แม่นยำการรบกวนต่ำและการควบคุมวงปิดที่ง่ายดายของมอเตอร์ DC ทำให้มอเตอร์เหล่านี้เป็นตัวเลือกที่ต้องการ:

4.1 อุปกรณ์ทางการแพทย์

- ปั๊มฉีดสารและปั๊มฉีดยา: จำเป็นต้องควบคุมอัตราการจ่ายของเหลวอย่างแม่นยำ (เช่น หลายหยดต่อนาที) มอเตอร์กระแสตรงทำงานร่วมกับตัวเข้ารหัสแบบโฟโตอิเล็กทริกเพื่อควบคุมความเร็วแบบวงปิด โดยควบคุมความคลาดเคลื่อนได้ภายใน ±1% เพื่อหลีกเลี่ยงการใช้ยาเกินขนาดหรือไม่เพียงพอ

- เครื่องช่วยหายใจ:ระบบขับเคลื่อนพัดลมของเครื่องช่วยหายใจใช้มอเตอร์ DC ซึ่งสามารถปรับปริมาณอากาศแบบเรียลไทม์ตามอัตราการหายใจของผู้ป่วย และทำงานเงียบเพื่อลดการรบกวนผู้ป่วยให้น้อยที่สุด

- เครื่องมือทางทันตกรรม (เช่น อุปกรณ์จับความเร็วสูง):มอเตอร์ DC แบบขดลวดขนาดเล็กทำงานด้วยความเร็วสูง (สูงสุด 300,000 รอบต่อนาที) ด้วยแรงบิดที่เสถียร ช่วยให้เจียรฟันหรือเจาะได้อย่างแม่นยำ

4.2 เครื่องมือวิจัยทางวิทยาศาสตร์

- เครื่องกวนและเครื่องเหวี่ยงในห้องปฏิบัติการ:เครื่องกวนต้องทำงานที่ความเร็วต่ำอย่างเสถียร (เพื่อป้องกันการกระเด็นของสารละลาย) ในขณะที่เครื่องเหวี่ยงต้องปรับความเร็วตามประเภทของตัวอย่าง (เช่น 3,000 รอบต่อนาทีสำหรับการแยกซีรัม และ 10,000 รอบต่อนาทีสำหรับการแยกเซลล์) ความแม่นยำในการควบคุมความเร็วของมอเตอร์กระแสตรงตอบสนองความต้องการของการทดลอง

- ขั้นตอนการวางตำแหน่งที่แม่นยำ:สำหรับการใช้งาน เช่น การเคลื่อนที่ของเวทีกล้องจุลทรรศน์หรือการปรับเลนส์ของอุปกรณ์เลเซอร์ จะใช้มอเตอร์เซอร์โว DC ร่วมกับสกรูบอลเพื่อให้สามารถควบคุมตำแหน่งได้ในระดับไมครอน

5. อุปกรณ์อิเล็กทรอนิกส์สำหรับผู้บริโภคและของเล่น: ขนาดเล็กและต้นทุนต่ำ

อุปกรณ์อิเล็กทรอนิกส์เพื่อการบริโภคและของเล่นต้องใช้มอเตอร์ ขนาดเล็ก ต้นทุนต่ำ และใช้พลังงานต่ำทำให้มอเตอร์ PMDC ขนาดเล็กกลายเป็นตัวเลือกหลัก:

5.1 อุปกรณ์อิเล็กทรอนิกส์สำหรับผู้บริโภค

- โทรศัพท์มือถือและแท็บเล็ตมอเตอร์สั่น (เช่น สำหรับการสั่นเมื่อมีสายเรียกเข้า) เป็นมอเตอร์ DC ขนาดเล็ก ซึ่งสร้างแรงสั่นสะเทือนผ่านการหมุนของล้อนอกรีต มีขนาดเพียงไม่กี่ลูกบาศก์มิลลิเมตร และใช้พลังงานต่ำมาก

- กล้องถ่ายรูป:ไดรฟ์โฟกัสและซูมของเลนส์กล้องใช้มอเตอร์ DC ขนาดเล็ก (เป็นทางเลือกแทนมอเตอร์สเต็ปเปอร์) เพื่อให้สามารถปรับโฟกัสได้อย่างรวดเร็วและเงียบ

5.2 ของเล่นและโมเดล

- รถยนต์บังคับวิทยุและโดรน:ล้อขับเคลื่อนของรถของเล่นและใบพัดของโดรนระดับเริ่มต้นใช้มอเตอร์กระแสตรงขนาดเล็ก ควบคุมความเร็วโดยการปรับแรงดันไฟฟ้าอาร์เมเจอร์ผ่านรีโมทคอนโทรล ทำให้มีต้นทุนต่ำและบำรุงรักษาง่าย

- ของเล่นไฟฟ้า (เช่น หุ่นยนต์ ชุดรถไฟ): จำเป็นต้องเริ่ม/หยุดและควบคุมความเร็วบ่อยครั้ง มอเตอร์ DC มีความเร็วในการตอบสนองที่รวดเร็ว ตอบสนองความต้องการแบบโต้ตอบของของเล่น

ตรรกะหลักเบื้องหลังแอปพลิเคชันมอเตอร์ DC

โดยสรุปแล้ว การเลือกใช้มอเตอร์ DC จะต้องปฏิบัติตามหลักการดังต่อไปนี้ “การจับคู่ความต้องการของสถานการณ์กับลักษณะเฉพาะของมอเตอร์”:

- สำหรับ ช่วงความเร็วกว้าง + ความแม่นยำสูง → เลือกมอเตอร์ DC แบบแยกการกระตุ้น/พันแยก (เช่น เครื่องมือกล อุปกรณ์ทางการแพทย์)

- สำหรับ แรงบิดเริ่มต้นสูง + ความเร็วสูง → เลือกมอเตอร์ DC แบบพันอนุกรม (เช่น เครื่องดูดฝุ่น รอกไฟฟ้า)

- สำหรับ ขนาดเล็กลง + การใช้พลังงานต่ำ → เลือกมอเตอร์ PMDC (เช่น มอเตอร์สั่นโทรศัพท์มือถือ แปรงสีฟันไฟฟ้า)

แม้ว่ามอเตอร์ซิงโครนัสแม่เหล็กถาวร (PMSM) จะมาแทนที่มอเตอร์ DC ในบางสาขา (เช่น ยานยนต์พลังงานใหม่) ในช่วงไม่กี่ปีที่ผ่านมา แต่มอเตอร์ DC ยังคงมีข้อได้เปรียบที่ไม่อาจทดแทนได้ในสถานการณ์พลังงานขนาดเล็กถึงขนาดกลางที่ต้องควบคุมความเร็วอย่างง่ายหรือต้นทุนต่ำ