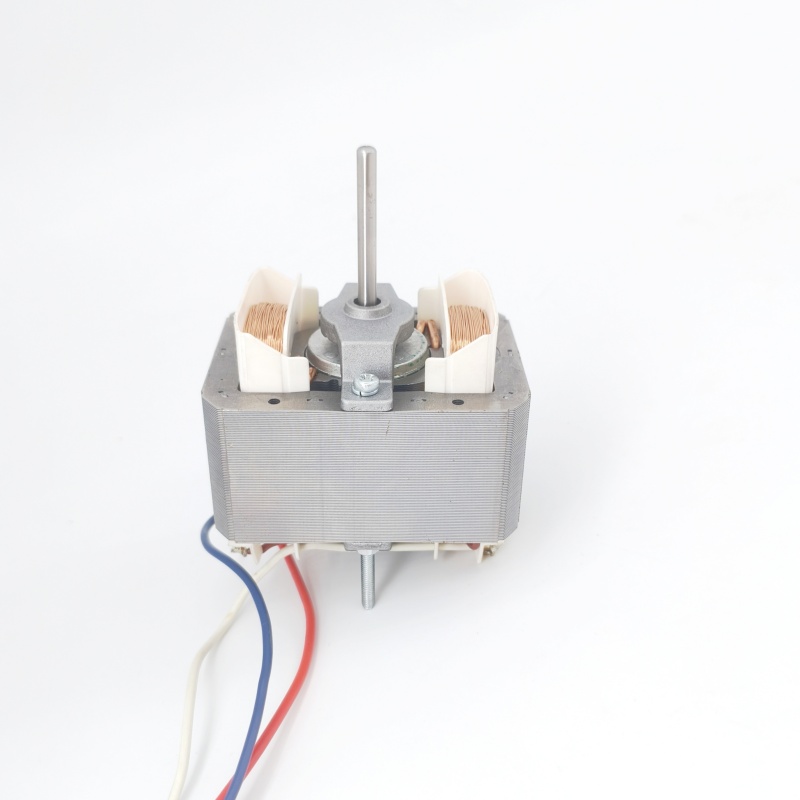

An AC (Alternating Current) motor converts electrical energy into mechanical energy using the principle of electromagnetic induction. Its structure varies slightly by type (e.g., induction, synchronous), but all AC motors share core components that enable their operation. Below is a detailed breakdown of the main parts, categorized by their functional roles.

1. Stationary Part: Stator

The статор is the fixed, outer component of the motor. It does not rotate and serves as the “electromagnetic field generator” that interacts with the rotating part.

Key Sub-components of the Stator:

-

Stator Core:

A laminated structure made of thin, high-silicon steel sheets (0.3–0.5 mm thick). Lamination reduces eddy current losses (waste heat caused by induced currents in the core) and hysteresis losses (energy lost due to magnetic field reversals). The core has evenly spaced slots on its inner circumference to hold the stator winding. -

Stator Winding (Armature Winding):

A set of copper or aluminum coils inserted into the stator core slots. When alternating current is supplied, the winding generates a rotating magnetic field (RMF)—the critical force that drives the rotor to spin.- For single-phase AC motors: The winding often includes a “main winding” (for torque) and an “auxiliary winding” (to start the motor, as single-phase current alone cannot produce a rotating field).

- For three-phase AC motors: Three separate windings (spaced 120° electrically apart) are used, which naturally create a strong rotating magnetic field without auxiliary components.

-

Stator Frame (Motor Housing):

A rigid outer casing (typically made of cast iron, aluminum, or steel) that:- Supports the stator core and protects internal components from dust, moisture, and physical damage.

- Acts as a heat sink to dissipate heat generated by the stator winding and core.

- Provides mounting points (e.g., feet, flanges) to secure the motor to equipment.

2. Rotating Part: Rotor

The ротор is the inner, moving component that rotates to output mechanical torque (connected to loads like fans, pumps, or conveyors). It responds to the stator’s rotating magnetic field. There are two main rotor types, depending on the AC motor category:

A. Rotor for Induction Motors (Most Common Type)

Induction motors use a squirrel-cage rotor (the simplest and most reliable design):

-

Rotor Core:

Similar to the stator core, it is a laminated structure (high-silicon steel sheets) with slots on its outer circumference. Lamination minimizes energy losses during rotation. -

Squirrel-Cage Winding:

A low-resistance conductor (usually aluminum or copper) cast directly into the rotor core slots. The ends of these conductors are shorted by two thick “end rings” (also aluminum/copper), forming a shape like a “squirrel cage.”- No external electrical connection is needed: The stator’s rotating magnetic field induces eddy currents in the cage winding, which creates its own magnetic field. The interaction between the stator’s RMF and the rotor’s induced field generates torque, spinning the rotor.

-

Rotor Shaft:

A solid metal rod (steel) pressed or welded into the center of the rotor core. It transfers the rotor’s rotational torque to external loads (via couplings, pulleys, or gears). The shaft is supported by bearings at both ends for smooth rotation.

B. Rotor for Synchronous Motors

Synchronous motors require a rotor that “locks onto” the stator’s rotating magnetic field (rotating at the same speed, or “synchronous speed”):

-

Field Winding:

A set of insulated copper coils wrapped around an iron core (the “rotor pole pieces”). Unlike induction motors, this winding receives direct current (DC) (via slip rings and brushes) to create a permanent magnetic field (north/south poles) on the rotor. -

Slip Rings and Brushes (for Wound Rotors):

- Slip Rings: Two metal rings (brass/copper) mounted on the rotor shaft, electrically connected to the field winding. They rotate with the rotor.

- Brushes: Carbon or graphite blocks fixed to the stator frame, pressing against the slip rings. They supply DC power from an external source to the rotating field winding.

- Note: Some modern synchronous motors use permanent magnet rotors (no field winding or slip rings), which are simpler and more efficient.

3. Supporting & Protective Components

These parts ensure the motor operates safely, smoothly, and efficiently:

-

Подшипники:

Located at both ends of the rotor shaft (inside the stator frame’s end caps). They reduce friction between the rotating shaft and fixed frame, enabling quiet, low-wear rotation. Common types include:- Ball bearings: For small to medium motors (high speed, low load).

- Roller bearings: For large motors (high load, heavy-duty applications).

-

End Caps (Bearing Housings):

Plastic or metal covers attached to the front and rear of the stator frame. They enclose the bearings and secure the rotor shaft in place, while also preventing dust from entering the motor interior. -

Cooling System:

Prevents overheating (a major cause of motor failure). Methods include:- Fan cooling: A small fan mounted on the rotor shaft (inside the rear end cap) that blows air over the stator and rotor.

- Natural cooling: For small motors (relying on heat dissipation through the stator frame).

- Forced-air/water cooling: For large, high-power motors (using external fans or water jackets around the stator).

-

Terminal Box:

A weatherproof compartment on the stator frame, containing electrical terminals. It provides a safe connection point for the AC power supply (to the stator winding) and, for synchronous motors, the DC power supply (to the rotor’s field winding). -

Thermal Protection (Optional):

Devices like thermal overload relays or PTC thermistors embedded in the stator winding. They detect excessive heat (e.g., from overloading or voltage fluctuations) and cut off power to prevent motor damage.

In short, the stator generates the driving magnetic field, the rotor converts magnetic force into mechanical rotation, and supporting components ensure reliable, long-term operation—all working together to make AC motors the workhorses of industrial, commercial, and household applications.