Why Does the Range Hood Lose Suction Significantly After 1-2 Years of Use?

Many families encounter such a problem: a newly purchased range hood has strong suction, quickly absorbing cooking fumes and keeping the kitchen air fresh. However, after more than a year of use, even when turned to the maximum gear, it becomes difficult to exhaust the fumes completely. Some fumes even spread to the living room, polluting the environment and causing oil stains to accumulate on cabinets and walls. The range hood shows no obvious malfunctions, so why does its suction decrease sharply? This is a common issue, usually caused by a combination of factors, and in most cases, it can be resolved through daily maintenance and simple treatments.

Root Causes: Four Core Factors Leading to Suction Attenuation

1. Oil Clogging in Filters and Oil Cups: The Most Common “Invisible Obstacle”

The filter of a range hood is the first line of defense against oil in cooking fumes. Whether it is a grid filter or a honeycomb filter, a large amount of oil will adhere to it after long-term use. When the oil accumulates to a certain extent, the ventilation holes of the filter will be blocked, increasing the resistance for fumes to pass through and naturally affecting the suction. At the same time, if the oil cup is not cleaned for a long time, the oil may overflow and drip along the edge of the filter, further blocking the filter gaps. In addition, some users have the misunderstanding of “not cleaning the oil cup until it is full”, but they are unaware that the volatile oil in the cup will form oil mist, which adheres back to the filter surface and accelerates the clogging process.

2. Oil Accumulation in Air Ducts and Impellers: The “Key Obstacle” to Suction Transmission

After passing through the filter, the fumes enter the internal air duct of the range hood and are finally sucked away and discharged outdoors by the negative pressure generated by the high-speed rotation of the impeller. However, the oil in the fumes will adhere to the inner wall of the air duct and the surface of the impeller along with the air flow, forming a thick layer of oil scale. The oil scale on the inner wall of the air duct will reduce the ventilation cross-sectional area, while the oil scale on the impeller will change its dynamic balance, reduce the rotation efficiency, and the viscosity of the oil scale will increase air resistance, resulting in the impeller being unable to generate sufficient negative pressure. This internal oil accumulation is often overlooked, but it is a “major culprit” of reduced suction, especially in families that frequently cook dishes with heavy oil.

3. Improper Installation or Duct Issues: “Invisible Interference” from the External Environment

The reduced suction of some users’ range hoods is not due to problems with the machine itself, but hidden dangers in installation or exhaust ducts. For example, an excessively long exhaust duct with too many bends will increase the resistance for fume discharge; poor sealing at the connection between the duct and the public flue will cause fume backflow or leakage, reducing the actual exhaust efficiency; some users do not reserve sufficient installation space during renovation, resulting in the air inlet of the range hood being too close to the cabinet, which affects air circulation and thereby weakens the suction. In addition, blockage or excessive pressure in the public flue can also hinder the fume discharge of the home range hood.

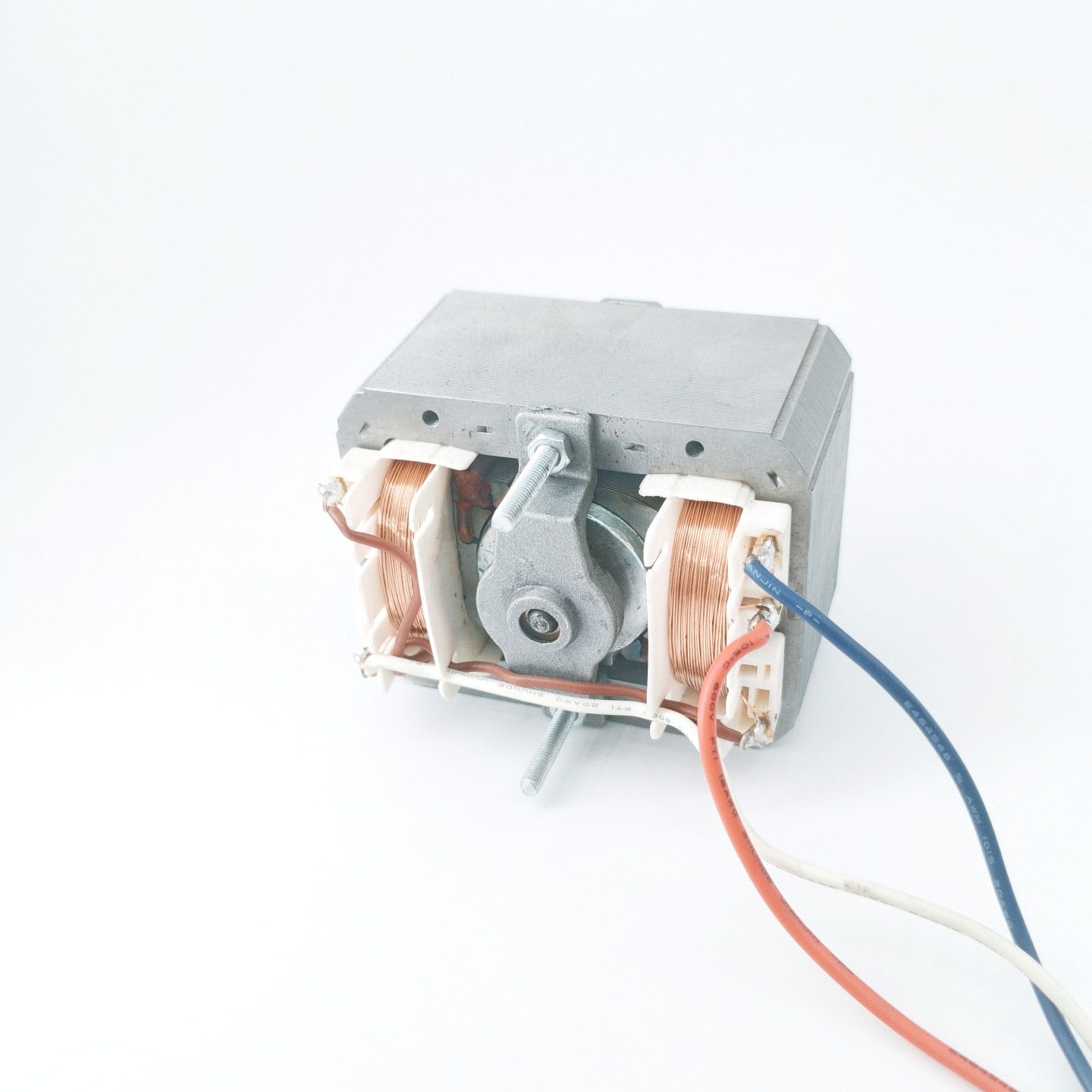

4. Motor Aging or Capacitor Failure: “Performance Decline” of Core Components

The motor is the “heart” of the range hood, responsible for driving the impeller to rotate. After long-term high-load operation, the motor bearings may wear, leading to a decrease in rotation speed; at the same time, the insulation performance of the motor windings may decrease, resulting in slight short circuits that affect the output power. In addition, if the motor start capacitor has capacity attenuation or damage, it will cause difficulties in motor startup and unstable rotation speed, which is directly reflected in weakened suction. Such problems usually occur in range hoods that have been used for a long time (e.g., more than 5 years), but they may also occur in advance if daily maintenance is improper.

Solutions: Scenario-Based Treatments to Restore Strong Suction

1. Daily Cleaning: Regularly Clean Filters and Oil Cups

It is recommended to wipe off the floating oil on the filter surface once a week and thoroughly clean the filter every 1-2 months. When cleaning, the filter can be removed, soaked in warm water for 10 minutes, and gently scrubbed with a neutral detergent (such as dish soap). Avoid using hard objects like steel wool to scratch the filter. The oil cup should be cleaned “as soon as it is full” and wiped dry with a dry cloth after cleaning to prevent oil residue. In addition, after each cooking session, the range hood can be kept running for 3-5 minutes to exhaust the residual fumes and oil mist in the duct, reducing internal oil accumulation.

2. Deep Cleaning: Clean Oil in Air Ducts and Impellers

If the suction still does not improve after daily cleaning, deep cleaning is required. For users with strong hands-on ability, first disconnect the power supply, remove the range hood panel and impeller, spray a special oil cleaner on the impeller and the inner wall of the air duct, let it stand for 20 minutes, rinse it with warm water, dry it, and then reinstall it. If you are worried about damaging the machine by disassembly, you can contact the brand after-sales service for professional deep cleaning. Usually, doing this once a year can effectively prevent oil accumulation.

3. Inspection and Adjustment: Optimize Installation and Duct Layout

First, check whether the exhaust duct is bent or blocked. If the duct is too long or has too many bends, replace it with a duct of larger diameter or reduce the number of bends. Check the connection between the duct and the public flue, and seal it with sealant or fireproof gaskets to prevent fume leakage. At the same time, ensure that the distance between the air inlet of the range hood and surrounding obstacles is not less than 20 cm to ensure smooth air intake. If you suspect a problem with the public flue, contact the property management for inspection and dredging.

4. Component Maintenance: Replace Aging Motors or Capacitors

If the range hood still has problems such as weak suction, loud noise, and difficult startup after cleaning and adjustment, it may be due to motor or capacitor failure. In this case, contact professional maintenance personnel for inspection. If the motor is confirmed to be aging or the capacitor is damaged, replace them with parts of the same model. It should be noted that original accessories should be selected when replacing core components to ensure safety and performance matching.

Summary: Prevention is Better Than Remediation to Extend Machine Life

The reduced suction of range hoods is not irreversible; in most cases, it is caused by improper daily maintenance. By regularly cleaning the filters and oil cups, performing deep cleaning once a year, and paying attention to installation and duct issues, the strong suction of the range hood can be effectively maintained. For core component failures, timely maintenance and replacement can also restore the machine’s performance. Developing good usage and maintenance habits not only keeps the kitchen environment fresh but also extends the service life of the range hood, avoiding unnecessary replacement costs.