Não é permitido operar motores CA diretamente com alimentação CC. Existem diferenças essenciais no princípio de funcionamento e no projeto estrutural entre os dois. A conexão direta à alimentação CC causará mau funcionamento do motor e até mesmo danos ao equipamento.

Motivo principal: A diferença essencial entre motores CA e motores CC

A operação de motores CA (como motores assíncronos e motores síncronos) e motores CC depende de princípios completamente diferentes de “interação de campo magnético”, e a natureza da fonte de energia (CA/CC) determina diretamente se o campo magnético pode formar movimento efetivo.

1. Conflito fundamental no princípio de funcionamento

O principal requisito dos motores CA é depender de corrente alternada para gerar um campo magnético rotativo.

Tomando como exemplo o motor assíncrono trifásico mais comum, quando a energia CA trifásica entra no enrolamento do estator, um campo magnético rotativo estável é formado dentro do motor, e o rotor segue a rotação sob a “tração” desse campo magnético (há uma diferença de velocidade, ou seja, “assíncrono”).

O problema com a fonte de alimentação CC: se uma fonte de alimentação CC for conectada diretamente, o enrolamento do estator gerará um campo magnético constante (em vez de um campo magnético rotativo).

Neste momento, o rotor não tem força para girar sob força e permanecerá parado;

Enquanto isso, um rotor estacionário atua como um “condutor de curto-circuito” e não gera correntes induzidas em um campo magnético constante para equilibrar a corrente do estator, resultando em um aumento acentuado na corrente do enrolamento do estator (semelhante a um estado de “rotor travado”).

2. Descompasso no projeto estrutural

O enrolamento do estator de motores CA (especialmente motores assíncronos) é projetado para CA, sem componentes-chave como “comutadores” para motores CC;

Se for aplicada corrente contínua, o enrolamento não consegue atingir mudanças alternadas no campo magnético e não tem capacidade de suportar alta corrente contínua.

Os motores CC exigem componentes como comutadores e escovas para converter energia CC em corrente alternada no enrolamento do rotor para gerar torque rotacional, enquanto os motores CA não têm essas estruturas e não podem se adaptar à energia CC.

Situação especial: Como “usar” fonte de alimentação CC para motores CA?

Se uma fonte de alimentação CC for necessária para acionar um motor CA, ela deve ser convertida para CA por meio de um dispositivo intermediário, ou seja, um “inversor CC-CA”.

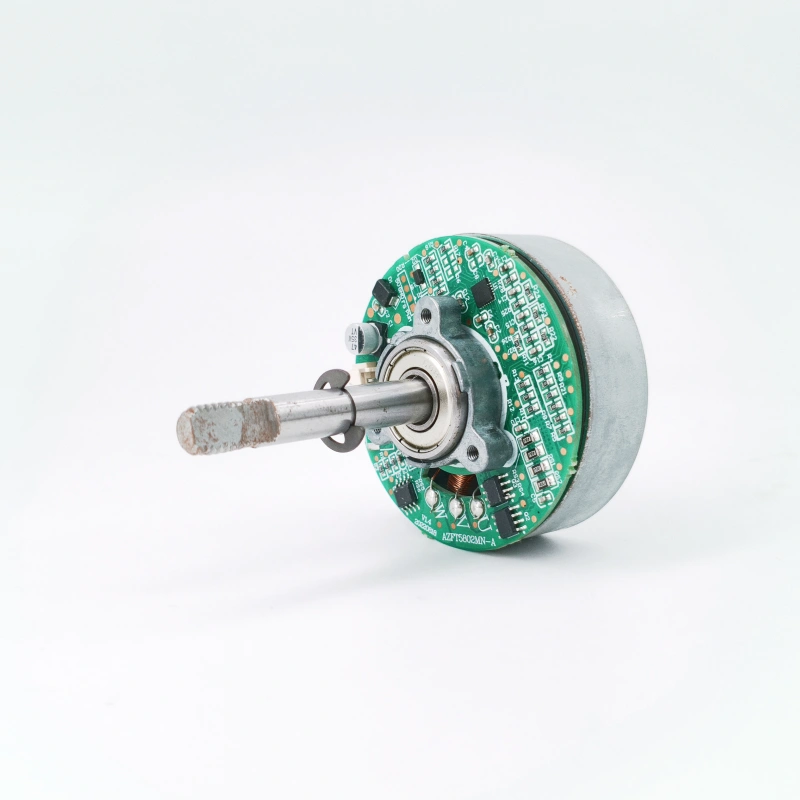

Este é um cenário comum na indústria (como o motor de acionamento de veículos de nova energia, que é essencialmente um motor CA, acionado pela energia CC da bateria convertida em energia CA por um inversor).

Situação especial: Como “usar” fonte de alimentação CC para motores CA?

Se uma fonte de alimentação CC for necessária para acionar um motor CA, ela deve ser convertida para CA por meio de um dispositivo intermediário, ou seja, um “inversor CC-CA”.

Este é um cenário comum na indústria (como o motor de acionamento de veículos de nova energia, que é essencialmente um motor CA, acionado pela energia CC da bateria convertida em energia CA por um inversor).

O processo específico é o seguinte:

Fonte de alimentação CC → inversor (conversão CC-CA) → saída de frequência/tensão CA ajustável → acionamento do motor CA para operação normal

As consequências do acesso direto

Se a fonte de alimentação CC for conectada por engano diretamente ao motor CA, isso resultará em:

O motor não pode dar partida e o rotor está parado;

O enrolamento do estator aquece rapidamente devido à sobrecorrente, o que pode queimar a camada isolante do enrolamento e causar danos ao motor;

Se a capacidade de energia for grande, isso também poderá causar problemas de segurança, como sobrecarga de energia e disparos.

resumo

Conexão direta: motores CA não podem ser operados diretamente com energia CC, pois isso pode danificar o equipamento.

Uso indireto: CC precisa ser convertida em CA por meio de um inversor para acionar um motor CA.