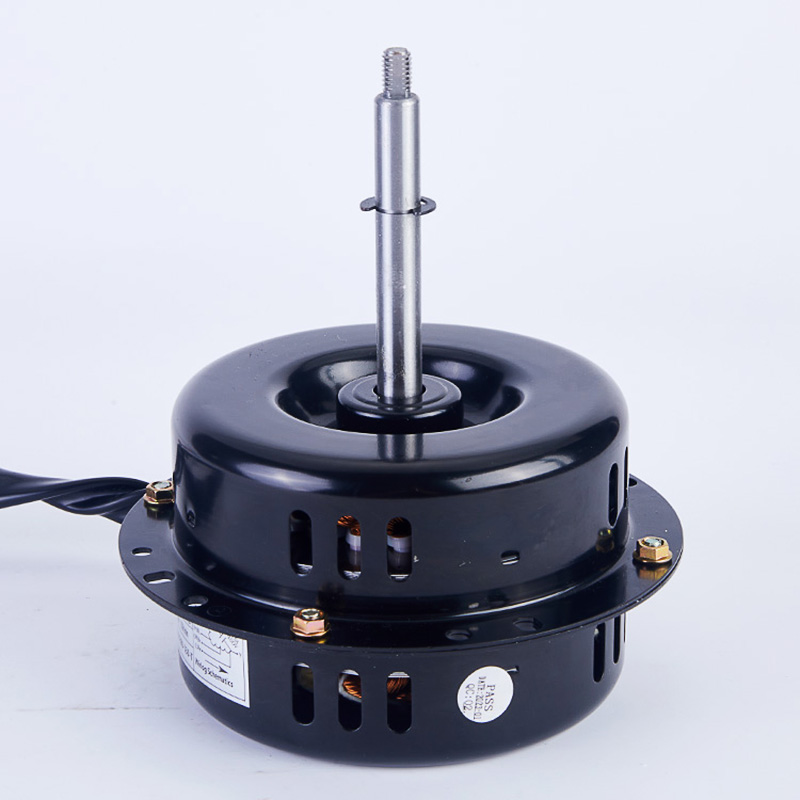

Stable operation, adaptable to multiple scenarios, durable, anti manufacturing, anti-wear, anti deformation ability, strong AC motor YAY-80

Get A Quote

If you have any questions about our products and service,please feel free to leave us a message

We are professional manufacturer of motor, we manufacture motor for fan,range hood,,air purifier and so on. Our products have good quality and competitive prices. If you are interested in any products, please contact me. TUO JING MOTOR welcomes your visit.

In modern ventilation systems, the performance of the fan motor, as the core power component, directly affects the efficiency of the entire ventilation system.

A high-quality ventilation fan motor, like the heart of a precision instrument, continuously injects strong power into the airflow, creating a comfortable, healthy, and efficient air environment.

From a technical perspective, high-quality ventilation fan motors demonstrate outstanding design and manufacturing processes.

The motor adopts advanced electromagnetic design concepts, accurately plans the electromagnetic circuit, optimizes the magnetic field distribution, effectively reduces hysteresis and eddy current losses, thereby greatly improving the efficiency of converting electrical energy into mechanical energy.

In some high-end motor products, the introduction of new magnetic materials, such as rare earth permanent magnet materials with high magnetic permeability and low coercivity, further enhances the electromagnetic performance of the motor, enabling it to output stable and strong power with lower energy consumption during operation, in line with the current global advocacy for energy conservation and emission reduction.

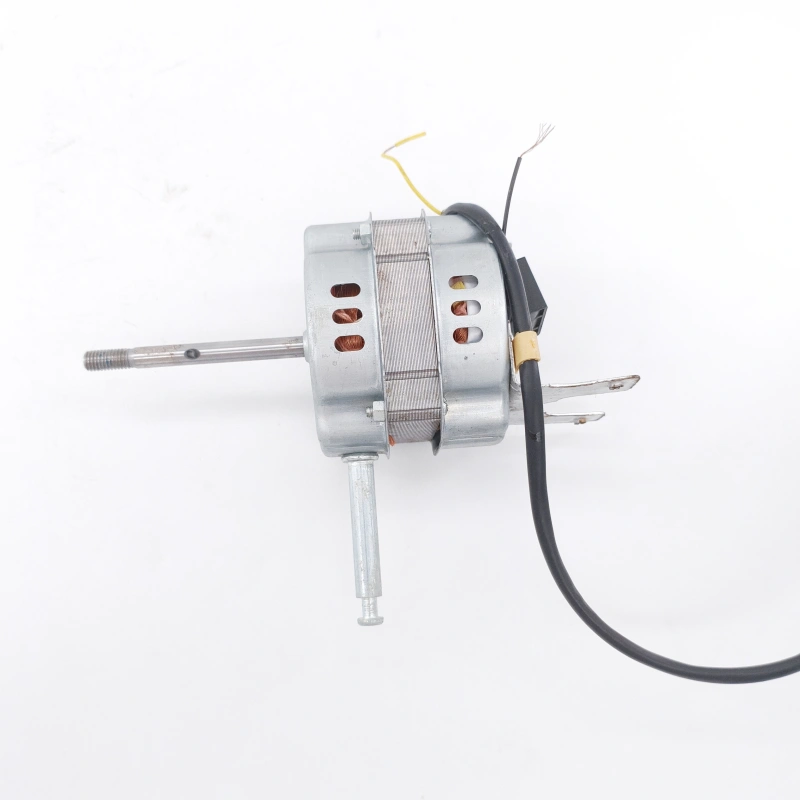

The manufacturing process is also a key advantage of high-quality fan motors.

The stator and rotor inside the motor, as the core components for converting electrical and mechanical energy, require extremely high manufacturing accuracy.

By using high-precision processing equipment and techniques, we ensure that the slot accuracy of the stator core and the dynamic balance accuracy of the rotor reach micrometer level.

Such high manufacturing precision not only effectively reduces the vibration and noise during motor operation, but also extends the service life of the motor, ensuring its stable operation in long-term, high-intensity working environments.

In addition, the winding of the motor is made of high-purity copper material and advanced insulation treatment technology is used to improve the insulation performance and heat dissipation ability of the winding, enabling the motor to operate reliably in complex working conditions and avoid faults caused by insulation failure or overheating.

In terms of application scenarios, high-quality ventilation fan motors demonstrate wide applicability and powerful functionality.

In the field of commercial buildings, such as large shopping malls and office buildings, ventilation systems need to maintain fresh and comfortable indoor air at all times to meet the breathing needs of a large number of people.

High quality fan motors can drive large ventilation equipment with stable air volume and pressure, achieving efficient replacement of indoor and outdoor air. At the same time, with their low noise characteristics, they ensure a quiet and pleasant indoor environment that does not interfere with people’s normal work and shopping experience.

In industrial production environments, such as chemical, metallurgical, and electronic manufacturing industries, large amounts of dust, exhaust gas, and heat are often generated in workshops, which places strict demands on the performance of ventilation systems.

High quality ventilation fan motors, with their strong power output and excellent reliability, can drive high-power ventilation and dust removal equipment, quickly discharge harmful gases and dust, effectively control the temperature and humidity in the workshop, provide safe and stable environmental protection for industrial production, help enterprises improve production efficiency, and reduce equipment failure rates.

From the trend of intelligent development, high-quality ventilation fan motors are actively integrating intelligent technology elements, ushering in a new era of intelligent ventilation.By equipped with advanced sensors and intelligent control systems, the motor can sense environmental parameters in real time, such as temperature, humidity, air quality, etc., and automatically adjust its operating status according to preset programs.

Related performance description:

Specification: DC Range hood motor

Warranty period: One year

Type: AC motor

Voltage: 20-60V

Motor efficiency: 30%

Output power: 30-50W

Minimum order quantity: 100 units

Monthly supply capacity: 100000

Gross weight of the product: 1.1Kg

Usage: Range hood motor

FAQ

Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Low MOQ, 1pc for sample checking is available

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.

1 let us know your requirements or application.

2 We quote according to your requirements or our suggestions.

3 customer confirms the samples and places deposit for formal order.

4 We arrange the production.

Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Yes, we offer 1years warranty to our products.After the warranty period, we can continue to provide after-sales service of products and replacement of spare parts

One More Question?

If you have any questions about our products and service,please feel free to contact us!