Un motore a corrente alternata (AC) è un dispositivo che converte l'energia elettrica in corrente alternata (AC) in energia meccanica e il suo funzionamento si basa su principi elettromagnetici fondamentali. Per capirne il funzionamento, analizziamo i suoi componenti chiave e la sequenza di eventi che ne consentono il movimento.

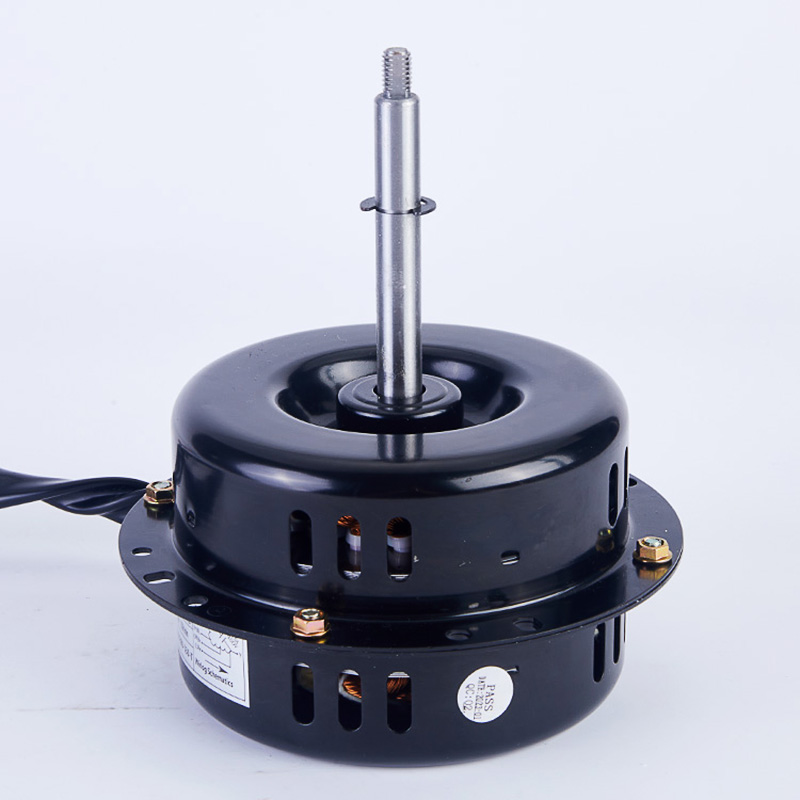

Per prima cosa, identifichiamo le parti principali. La maggior parte dei motori a corrente alternata, in particolare i comuni motori a induzione, sono costituiti da due componenti principali: statore e il rotoreLo statore è la parte esterna fissa del motore, contenente un insieme di elettromagneti (chiamati avvolgimenti statorici) disposti circolarmente attorno all'asse centrale. Questi avvolgimenti sono collegati a una fonte di alimentazione CA. Il rotore, invece, è la parte interna rotante, tipicamente un nucleo cilindrico costituito da lamiere laminate con barre conduttrici (spesso in rame o alluminio) incorporate nella sua superficie, che formano una struttura a "gabbia di scoiattolo" in molti motori a induzione. Queste barre sono cortocircuitate ad entrambe le estremità da anelli, consentendo il passaggio della corrente elettrica.

La magia di un motore AC inizia con il campo magnetico rotante generato dallo statore. Quando la corrente alternata scorre attraverso gli avvolgimenti dello statore, ogni avvolgimento diventa un elettromagnete la cui polarità si inverte al variare della corrente (poiché la corrente alternata cambia direzione periodicamente). Fondamentalmente, gli avvolgimenti dello statore sono distanziati ad angoli specifici (solitamente 120 gradi nei motori trifase) e collegati a fasi dell'alimentazione CA che non sono sincronizzate tra loro. Questa differenza di fase fa sì che il campo magnetico prodotto dallo statore ruoti uniformemente attorno all'asse a una velocità nota come velocità sincrona, che dipende dalla frequenza della corrente alternata e dal numero di poli negli avvolgimenti dello statore. Ad esempio, un alimentatore a 60 Hz con uno statore a 4 poli crea una velocità sincrona di 1800 giri al minuto (RPM).

Prossimo, induzione elettromagnetica Entra in gioco, azionando il rotore. Quando il campo magnetico rotante dello statore attraversa le barre conduttive del rotore, induce una corrente elettrica nelle barre del rotore (grazie alla legge di induzione di Faraday). Questa corrente indotta, a sua volta, crea un proprio campo magnetico attorno al rotore (legge di Ampère). L'interazione tra il campo magnetico rotante dello statore e il campo magnetico del rotore genera una coppia, una forza di torsione, che fa sì che il rotore segua il campo rotante.

Nei motori a induzione, il rotore non raggiunge mai la velocità sincrona del campo magnetico dello statore. Questa differenza, nota come scontrino, è necessario per mantenere l'induzione di corrente nel rotore. Se il rotore corrispondesse alla velocità sincrona, non ci sarebbe alcun movimento relativo tra il rotore e il campo magnetico, quindi non verrebbe indotta corrente e non verrebbe prodotta coppia. Invece, il rotore gira a una velocità leggermente inferiore (tipicamente il 2-5% in meno rispetto alla velocità sincrona nei motori standard), garantendo un'induzione continua di corrente e coppia.

In sintesi, un motore a corrente alternata funziona attraverso l'azione coordinata di un campo magnetico rotante (generato dagli avvolgimenti dello statore alimentati a corrente alternata) e dell'induzione elettromagnetica (che induce corrente nel rotore, creando un campo magnetico che interagisce con il campo dello statore per produrre coppia). Questo elegante processo converte efficacemente l'energia elettrica in movimento meccanico, rendendo i motori a corrente alternata indispensabili in innumerevoli applicazioni, dagli elettrodomestici ai macchinari industriali.