1. Introduction

2. Basic Structure of DC Motors and Components Related to Service Life

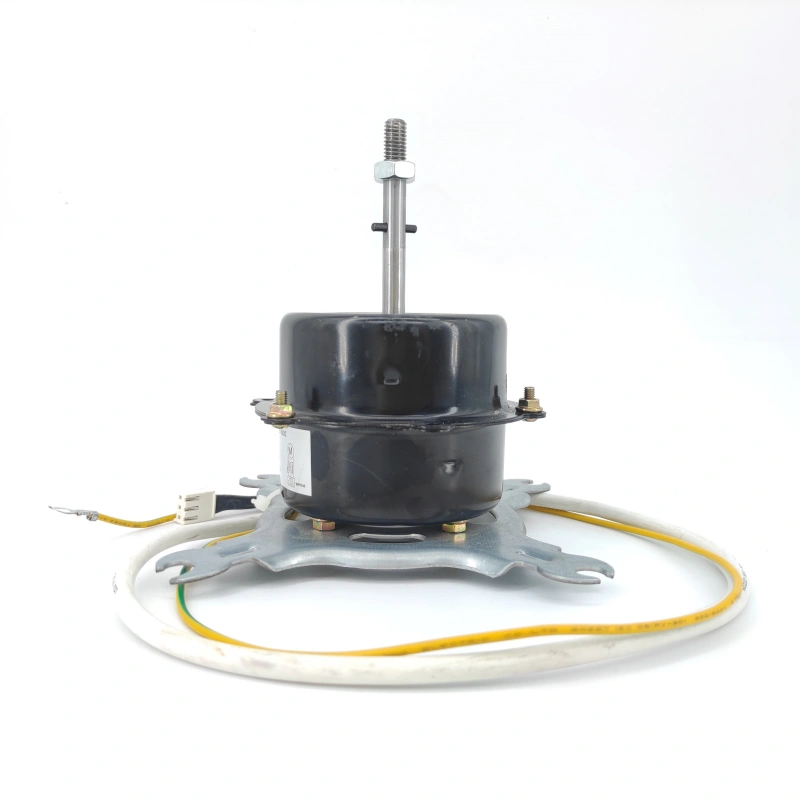

2.1 Basic Structural Composition

2.2 Components Closely Related to Service Life

- Bearings: Bearings are critical components connecting the stator and rotor. Their role is to support the rotor and reduce frictional resistance during rotation. Wear and damage to bearings directly affect the motor’s normal operation and are a common cause of shortened motor service life.

- Brushes and Commutator: Brushes cooperate with the commutator to achieve current commutation. During motor operation, continuous friction and electrical arcing occur between the two, leading to gradual wear and damage over long-term use. This impairs the motor’s electrical conductivity and commutation reliability.

- Windings: Windings are the core components that generate electromagnetic force in the motor, made by winding insulated wires. The insulation performance of windings is directly related to the motor’s safe operation and service life. Insulation aging, damage, or short circuits can all cause motor failures.

- Iron Core: The iron core is an important part of the motor’s magnetic circuit, usually made by stacking silicon steel sheets. Iron core wear and overheating affect the motor’s efficiency and service life—especially during high-frequency operation or overload, where overheating becomes more pronounced.

3. Key Factors Affecting the Service Life of DC Motors

3.1 Electrical Factors

-

Power Quality

- Voltage Fluctuations: Unstable power supply voltage adversely affects DC motor operation. When voltage is too high, the current in the motor windings increases, leading to higher copper losses, elevated winding temperatures, and accelerated aging of insulation materials. Conversely, low voltage results in insufficient motor output torque, which may cause the motor to operate under overload—also leading to winding overheating. For example, in remote areas or locations with unstable power supply, DC motors often have significantly shorter service lives due to frequent voltage fluctuations.

- Current Harmonics: The widespread use of power electronic equipment (such as rectifiers and frequency converters) introduces large amounts of current harmonics into the power supply. Harmonic currents cause additional losses in motor windings, leading to overheating. They also generate pulsating torque, increasing motor vibration and noise, exacerbating component wear, and thus shortening the motor’s service life.

-

Overload Operation

Overload operation occurs when the motor’s actual output power or torque exceeds its rated value. Under overload conditions, the current in the motor windings increases significantly, causing a sharp rise in copper losses and rapid temperature elevation of the windings. Long-term overload accelerates the aging of winding insulation materials and may even burn the windings. Additionally, overload increases the load on bearings, accelerating their wear and affecting the motor’s overall service life. For instance, in hoisting equipment, frequent overloading easily causes DC motor failures and drastically shortens their lifespan.

-

Short Circuits and Ground Faults

A winding short circuit occurs when insulation damage between or within windings causes current to bypass the normal path and form a direct loop. Short circuits generate excessive local current, producing large amounts of heat that burn windings and insulation materials. A winding ground fault refers to insulation damage between windings and the motor housing or iron core, resulting in current leakage to the ground. Ground faults not only disrupt normal motor operation and pose safety risks but also accelerate motor damage.

3.2 Mechanical Factors

-

Bearing Wear

During motor operation, bearings bear the weight of the rotor and radial/axial forces generated by rotation, leading to wear over time. Bearing wear causes rotor eccentricity, increasing motor vibration and noise. It also disrupts the uniformity of the motor’s air gap, generating additional electromagnetic losses and overheating. When bearing wear reaches a certain level, the motor may seize and stop functioning. Common causes of bearing wear include poor lubrication, improper installation, excessive load, and low-quality bearings.

-

Wear of Brushes and Commutator

Brushes and the commutator are in sliding contact during motor operation, resulting in continuous friction. Over time, brushes gradually wear down, and the commutator surface develops wear, scratches, or oxidation. Excessive brush wear causes poor contact and electrical arcing, which further accelerates commutator wear. Damage to the commutator surface impairs normal current commutation, leading to unstable motor operation, reduced efficiency, and even failures.

-

Vibration and Impact

Vibration generated during motor operation and external impact loads both adversely affect service life. Long-term vibration causes loosening, wear, and fatigue damage to internal motor components—such as loose bolts, broken winding leads, and loosened silicon steel sheets in the iron core. External impacts (e.g., shocks during equipment start/stop or 颠簸 during transportation) may deform or damage motor components, disrupting normal operation.

3.3 Environmental Factors

-

Temperature

High ambient temperatures are a major factor shortening DC motor service life. Motors generate heat during operation; when ambient temperatures are high, heat dissipation deteriorates, causing internal motor temperatures to rise. High temperatures accelerate insulation aging, reduce insulation performance, impair bearing lubrication, and 加剧 wear. For example, DC motors used in tropical regions or high-temperature industrial environments typically have shorter service lives than those used in normal-temperature environments.

-

Humidity and Corrosive Gases

High humidity causes moisture absorption in the motor’s insulation materials, reducing insulation resistance and increasing the risk of leakage and short circuits. Meanwhile, humid environments accelerate corrosion of metal components (e.g., bearings, commutators, and frames). In corrosive environments (e.g., chemical plants or coastal areas), corrosive gases attack the motor’s metal components and insulation materials, causing component damage and reduced insulation performance—seriously impacting service life.

-

Dust and Impurities

Dust, fibers, and other impurities in the air enter the motor and adhere to surfaces of windings, commutators, and bearings. Dust impairs heat dissipation, leading to temperature rises; it may also enter bearings, exacerbating wear. For commutators and brushes, accumulated dust disrupts contact, generates electrical arcing, and accelerates wear.

4. Specific Measures to Extend DC Motor Service Life

4.1 Optimize Electrical Operating Conditions

-

Ensure Stable Power Quality

To reduce the impact of power quality on motor life, measures should be taken to stabilize power supply voltage and frequency. Install voltage regulators, filters, or other equipment in the motor power supply circuit to suppress voltage fluctuations and current harmonics. For critical motor equipment, use independent power supply circuits to avoid interference from other devices. Additionally, regularly inspect and maintain the power supply system to promptly identify and resolve power faults.

-

Avoid Overload Operation

When selecting a motor, choose a model with a rated power greater than or equal to the actual load requirement based on real-world load conditions. During operation, monitor the load to prevent overload. Install overload protection devices (e.g., thermal relays or overcurrent relays) that cut off power promptly if overload occurs, protecting the motor. Meanwhile, arrange motor operating hours reasonably to avoid long-term continuous operation, allowing the motor sufficient rest time to reduce overheating.

-

Prevent Short Circuits and Ground Faults

Strengthen insulation testing and maintenance of motor windings to prevent short circuits and ground faults. Regularly measure winding insulation resistance with an insulation resistance tester to ensure it meets specified requirements. For newly installed or long-idle motors, conduct insulation tests before operation. During operation, keep the motor interior clean and dry to prevent oil, moisture, or other substances from entering the windings. Additionally, configure appropriate protection devices (e.g., short-circuit protection and ground protection) to quickly cut off power in case of faults, minimizing damage.

4.2 Strengthen Maintenance of Mechanical Components

-

Bearing Maintenance

Regular inspection and lubrication are key to extending bearing life. Develop a reasonable lubrication schedule based on motor operating conditions and bearing type, and select appropriate lubricating oil or grease. Ensure cleanliness during lubrication to prevent impurities from entering the bearings. Meanwhile, regularly check bearing temperature, vibration, and noise to detect early bearing faults promptly. Replace bearings immediately if wear, abnormal noise, or other issues occur to avoid fault escalation.

-

Maintenance of Brushes and Commutator

Regularly inspect brush wear; replace brushes promptly when wear reaches a certain limit. When replacing brushes, use products matching the original brush model to ensure consistent material, size, and performance. During installation, adjust brush pressure to ensure good contact between brushes and the commutator. Additionally, regularly clean and polish the commutator surface to remove oxide layers, dirt, and scratches, maintaining a smooth surface. Avoid damaging the commutator’s insulation layer during cleaning and polishing.

-

Reduce Vibration and Impact

During motor installation, ensure a stable and reliable foundation and accurate positioning to avoid resonance between the motor and other equipment. Use shock-absorbing devices (e.g., shock-absorbing pads or dampers) to reduce vibration transmission during motor operation. Take effective protective measures during motor transportation and handling to avoid severe impacts or vibration. Additionally, regularly inspect and tighten the motor’s fastening bolts to prevent increased vibration due to loose bolts.

4.3 Improve the Operating Environment

-

Control Ambient Temperature

To ensure the motor operates in a suitable temperature environment, adopt effective cooling measures. For indoor motors, enhance ventilation and heat dissipation (e.g., install fans or ventilation ducts); for motors in high-temperature environments, use forced cooling methods (e.g., water cooling or oil cooling). Avoid installing the motor in direct sunlight or near heat sources to reduce the impact of ambient temperature. Regularly clean dust and debris from the motor surface to maintain good heat dissipation performance.

-

Moisture and Corrosion Protection

For motors used in humid environments, adopt moisture-proof measures (e.g., install moisture-proof heaters or use moisture-proof insulation materials) to keep the motor interior dry. For motors in corrosive environments, select models with corrosion resistance (e.g., those with stainless steel housings or anti-corrosion coatings). Regularly apply anti-corrosion treatments to the motor (e.g., painting anti-rust paint or replacing corroded components) to reduce damage from corrosive substances.

-

Dust Prevention and Cleaning

Install dust covers or filters at the motor’s air inlets and outlets to prevent dust and impurities from entering the interior. Regularly clean the motor to remove surface dust, oil, and other debris. Follow specified procedures when cleaning the motor interior to avoid damage. During cleaning, protect precision components (e.g., windings and commutators) from harm.

4.4 Regular Inspection and Maintenance

-

Regular Patrol Inspections

Develop a comprehensive motor patrol inspection system to check the motor’s operating status regularly. Inspection items include motor temperature, vibration, noise, current, voltage, and the appearance of components. Through patrols, identify issues promptly and take corrective action to prevent fault escalation.

-

Regular Testing

Conduct regular electrical performance tests on the motor, such as insulation resistance testing, DC resistance testing, no-load testing, and load testing, to fully assess the motor’s performance. These tests help detect potential issues (e.g., winding short circuits, ground faults, or inter-turn faults) and provide a basis for motor maintenance and repair.

-

Timely Repair and Component Replacement

Repair or replace faulty or damaged motor components promptly. During repairs, strictly follow the motor’s technical requirements to ensure repair quality. Replace irreparable components immediately to prevent damage to other motor parts. Maintain detailed motor maintenance records to support future maintenance and management.

5. Case Studies

5.1 Case 1: Extending DC Motor Service Life in a Factory

- Installed voltage regulators and filters to stabilize power supply voltage and reduce current harmonics.

- Re-evaluated motor loads, replacing some mismatched motors to avoid overload.

- Established a regular maintenance system: lubricated bearings monthly, inspected brush and commutator wear quarterly, and replaced worn components promptly.

- Improved workshop ventilation by installing exhaust fans to lower ambient temperatures.

- Conducted regular motor cleaning and dust prevention to prevent dust ingress.

5.2 Case 2: Maintenance of a DC Motor in an Electric Vehicle

- Replaced worn bearings and fully lubricated the new ones.

- Replaced brushes and polished/cleaned the commutator surface.

- Applied insulation treatment to the windings to restore insulation resistance.

- Inspected and adjusted the motor’s power supply system to ensure stable power quality.