As the “heart” of an air conditioner, the energy efficiency class of the air conditioner motor directly determines the operation efficiency, energy consumption level, user experience and service life of the air conditioner. It has a crucial impact on the overall performance of the air conditioner, and the adaptive selection also needs to consider multiple factors.

I. Core Impact of Energy Efficiency Class on Air Conditioner Energy Consumption

In terms of energy consumption impact, differences in the energy efficiency class of air conditioner motors directly lead to significant gaps in power consumption. At present, most household air conditioner motors in China adopt the IE series energy efficiency standards, among which IE1 is standard energy efficiency, IE2 is high energy efficiency, and IE3 is ultra-high energy efficiency. Data shows that under the same power, IE3 motors have an energy efficiency improvement of about 20%-30% compared with IE1 motors. Taking a 1.5-horsepower air conditioner as an example, an air conditioner equipped with an IE1 motor consumes about 0.8-1.0 kWh per hour, while the same specification air conditioner equipped with an IE3 motor can reduce the hourly power consumption to 0.6-0.7 kWh. Calculated by an average annual household usage of 1000 hours, the annual electricity bill can be saved by 100-200 yuan (based on an electricity price of 0.5 yuan/kWh). In the long run, the energy-saving advantage of high-efficiency motors is extremely obvious, especially suitable for scenarios with long-term continuous operation such as commercial places, where the energy-saving benefits are more prominent.

II. Multi-dimensional Effects of Energy Efficiency Class on Air Conditioner Operation Effect

In terms of operation effect, the advantages of high-efficiency motors are reflected in operation stability, temperature control accuracy and noise control. High-efficiency motors adopt optimized winding design, high-quality iron core materials and precision bearings, resulting in lower loss and less heat generation during operation. They can not only reduce the probability of motor failures and extend the service life, but also improve the temperature control response speed of the air conditioner. For example, in cooling mode, high-efficiency motors can quickly drive the fan to operate, making the indoor temperature drop evenly and avoiding local temperature differences; at the same time, low-loss operation brings lower operating noise, which is usually 3-5 decibels lower than that of standard energy efficiency motors, improving user comfort. On the contrary, low-efficiency motors generate large heat and have poor operation stability. Long-term use is prone to problems such as motor overload and accelerated aging, and may also cause frequent start-stop of the air conditioner, affecting the temperature control effect and shortening the overall service life of the air conditioner.

III. Adaptive Selection Method of High-efficiency Motors

When selecting a suitable high-efficiency motor, comprehensive judgment should be made based on multiple factors such as air conditioner type, usage scenario and power demand. Firstly, clarify the matching between air conditioner specifications and power. The motor power must be accurately matched with the specifications of the air conditioner compressor and fan; an excessively large or small motor will affect the exertion of energy efficiency. For example, a 1-1.5 horsepower household wall-mounted air conditioner can be equipped with a 30-50W IE3 motor, while a commercial central air conditioner needs to select a high-power ultra-high efficiency motor of several hundred watts to several kilowatts according to the unit tonnage. Secondly, select the motor according to the usage scenario. For places with long-term continuous operation (such as shopping malls and office buildings), priority should be given to IE3 and above grade motors to balance energy saving and stability; for household scenarios with high usage frequency, IE2 and above grade motors are also recommended; if the usage frequency is low, IE2 grade motors can be selected according to budget balance.

IV. Supplementary Matters Needing Attention for Selection

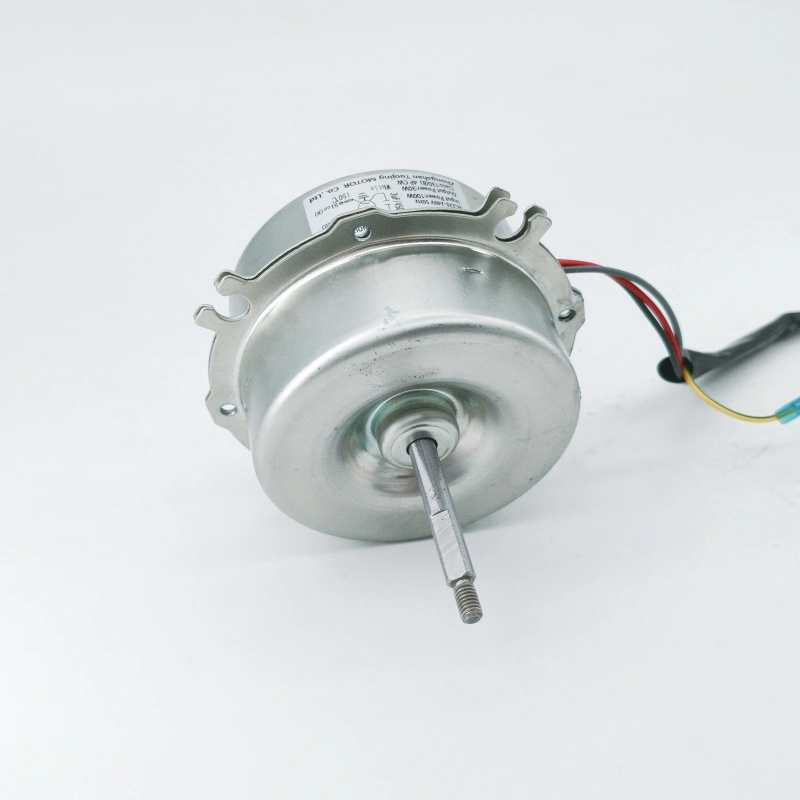

In addition, attention should also be paid to the protection level, heat dissipation performance and brand reliability of the motor. Air conditioner motors mostly operate in humid and closed environments, so the protection level should reach IP44 or above to prevent water vapor and dust from entering and causing failures; motors with excellent heat dissipation performance can adapt to high-temperature working conditions and avoid overheating protection; selecting well-known brand motors can ensure better winding technology and material quality, and their energy efficiency parameters are more in line with the actual operation situation, avoiding purchasing products with false energy efficiency labels. At the same time, the starting performance of the motor should also be considered. Especially for inverter air conditioners, it is necessary to select high-efficiency inverter motors suitable for the inverter system to ensure the coordinated work between the motor and the inverter module and further improve the overall energy efficiency of the air conditioner.

V. Summary

In summary, the energy efficiency class of the air conditioner motor has a significant impact on the energy consumption and operation effect of the air conditioner. Although the initial purchase cost of high-efficiency motors is slightly higher, the long-term energy-saving benefits, user experience and service life advantages are sufficient to cover the price difference. When selecting, it is necessary to balance the energy efficiency class, power matching, scenario requirements and product quality to maximize the overall performance of the air conditioner.