When purchasing a fan, many consumers tend to focus more on intuitive parameters such as appearance design and wind speed levels, but easily overlook the energy efficiency class of the fan motor. However, as the core power component of a fan, the energy efficiency class of the motor is not only directly related to comfort during use but also has a significant impact on long-term usage costs. So, how exactly does the energy efficiency class of a fan motor work, and how should ordinary consumers make appropriate choices based on it?

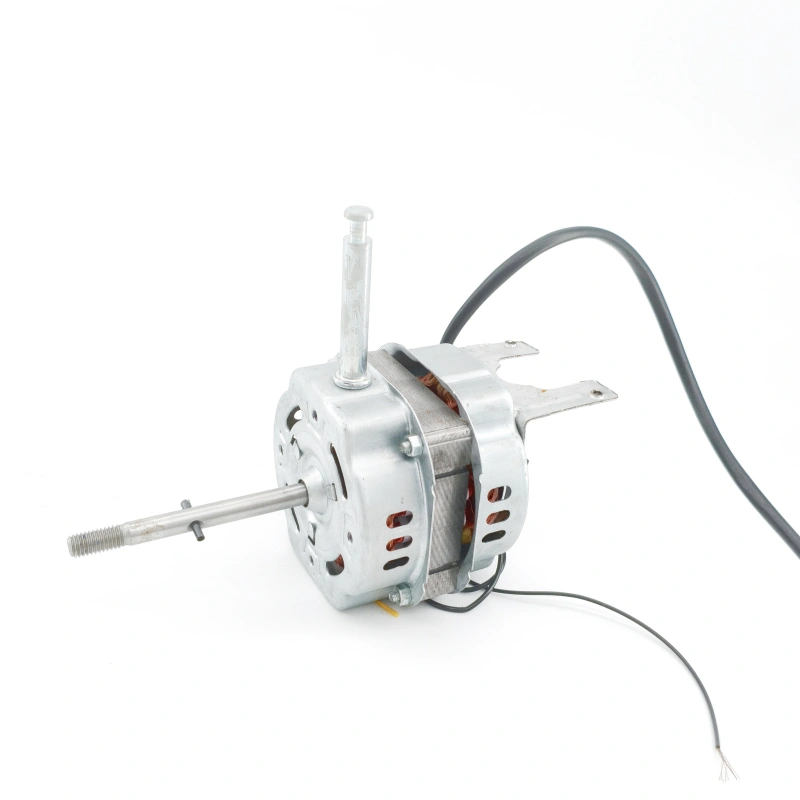

First of all, the energy efficiency class of a fan motor determines the efficiency of converting electrical energy into mechanical energy, which in turn affects the “noise reduction effect” and “wind speed stability” in the user experience. According to national standards, the energy efficiency classes of fan motors are divided into Levels 1 to 3, with Level 1 representing the highest energy efficiency and Level 3 the lowest. High-energy-efficiency motors adopt more optimized coil winding processes, higher-quality silicon steel sheet materials, and more precise rotor-stator matching designs. During operation, they can reduce electrical energy loss and minimize friction and heat generation among internal components. This optimization is directly reflected in the user experience: on the one hand, reduced friction means lower noise during motor operation. Especially in low wind speed gears (such as the sleep gear), the noise of a Level 1 energy efficiency motor can usually be controlled below 35 decibels, which is much lower than the 45+ decibels that a Level 3 energy efficiency motor may produce, avoiding noise interference during nighttime use. On the other hand, the high efficiency of electrical energy conversion ensures stable power output from the motor. Even when running at high wind speeds for a long time, it is less likely to have fluctuating wind speeds, maintaining a consistent air supply effect and enhancing comfort during use.

Secondly, from the perspective of long-term costs, the energy efficiency class of a fan motor is directly related to electricity expenses, and the difference will gradually expand with the duration of use. Taking a common pedestal fan as an example, assuming its motor power is 60W, it is used for an average of 8 hours per day, and the electricity price is 0.56 yuan per kilowatt-hour. The electrical energy conversion efficiency of a Level 1 energy efficiency motor is approximately 85%, so the actual power consumption can be converted to 51W; while the conversion efficiency of a Level 3 energy efficiency motor is about 70%, with an actual power consumption of approximately 68.6W. The daily electricity cost difference is about (68.6 – 51) × 8 ÷ 1000 × 0.56 ≈ 0.079 yuan, which seems negligible. However, if calculated based on 180 days of use per year (summer + early autumn), the annual electricity cost difference is approximately 14.2 yuan. If the service life of the fan is 8 years, the Level 3 energy efficiency fan will cost about 113.6 yuan more than the Level 1 one just in terms of electricity fees. In addition, high-energy-efficiency motors generate less heat, so the internal components age more slowly and have a lower probability of malfunction, which can reduce maintenance costs and further lower long-term usage costs.

For ordinary consumers, when choosing a fan motor, they should prioritize the energy efficiency class label and make a comprehensive judgment based on usage scenarios and needs. The first step is to be sure to choose products clearly marked with “Level 1 Energy Efficiency” and avoid purchasing fans without an energy efficiency label or with an energy efficiency class lower than Level 2, so as to ensure energy conservation and user experience from the source. The second step: if the fan is mainly used in the bedroom and there is a high demand for noise reduction, you can further check the noise reduction technical parameters of the motor (such as whether it uses “mute bearings” or “sealed coils”) and test the fan on-site to feel the noise level in the low wind speed gear. The third step: if the fan needs to run under high load for a long time (such as all-day use in the living room), in addition to the energy efficiency class, you should also pay attention to the power adaptability of the motor. Choose a product with a motor power matching the usage space (for example, a 60-75W motor is suitable for a 15-20㎡ space) to avoid motor overload caused by insufficient power, which would instead increase energy consumption and the risk of malfunction.

In conclusion, the energy efficiency class of a fan motor is one of the core indicators to measure fan quality. It not only affects the current comfort of use but also relates to long-term economic costs. When purchasing, ordinary consumers should attach importance to the energy efficiency class and make scientific choices based on their own needs, so that they can not only enjoy a comfortable air supply experience but also achieve the dual goals of energy conservation, environmental protection and cost savings.