As the “power core” of industrial production, overheating faults are a frequent problem for AC motors during operation. Minor overheating can lead to reduced motor efficiency and shortened service life, while severe cases may cause winding burnout and equipment shutdown, resulting in huge production losses. The essence of AC motor overheating is an “imbalance between heat generation and heat dissipation”—that is, the heat generated by copper loss, iron loss, etc., during motor operation cannot be dissipated in a timely manner, causing the temperature to exceed the tolerance limit of the insulating material. To solve this problem at the source, it is necessary to first clarify the core causes of overheating, and then formulate precise protective measures based on the characteristics of industrial scenarios to achieve the dual guarantee of “source heat control + efficient heat dissipation”.

1. Core Causes of AC Motor Overheating

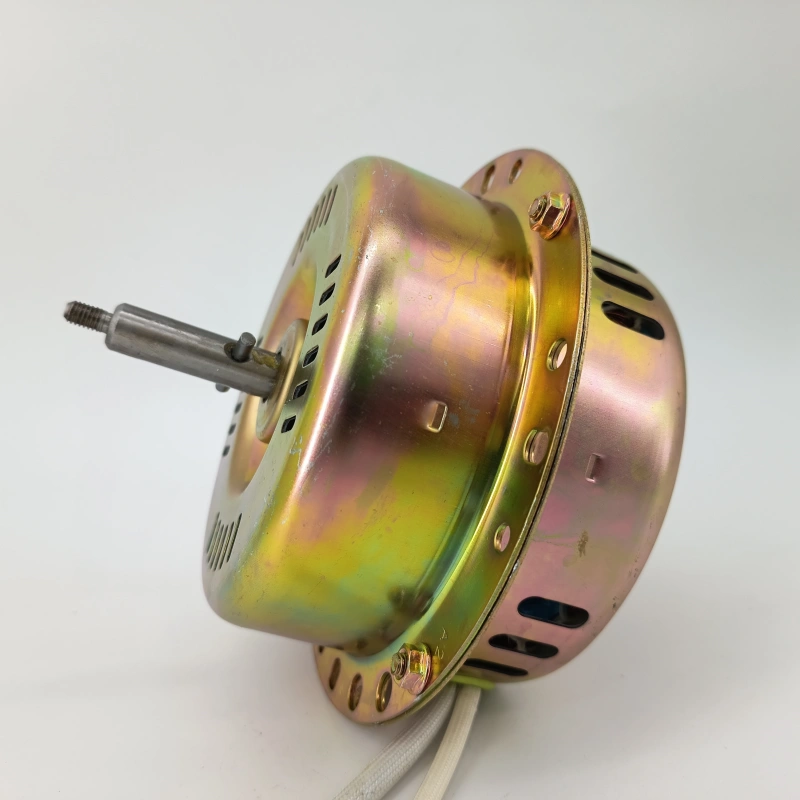

The core causes of AC motor overheating can be divided into two categories: “abnormal internal loss” and “external heat dissipation failure”, among which abnormal internal loss is the primary cause. First, excessive copper loss, which refers to the excessive resistance loss of the stator and rotor windings, is mostly caused by inter-turn short circuits in the windings and loose terminal connections. Aging and damage to the winding insulation layer will cause inter-turn short circuits, concentrating current flow through local conductors and generating a large amount of heat; loose terminal connections will increase contact resistance, forming a “hot spot” that continuously heats up. Second, excessive iron loss, which stems from abnormal hysteresis loss and eddy current loss of the motor core, is common in scenarios with fluctuating power supply voltage. When the voltage is too high, the core magnetic flux density becomes saturated, and hysteresis loss increases sharply. Especially in asynchronous AC motors, an increase in slip rate will further aggravate the rotor iron loss. Third, excessive mechanical loss, where bearing wear and rotor imbalance are the main causes. Worn bearings increase frictional resistance, and unbalanced rotors generate additional centrifugal force during rotation. Both convert mechanical energy into heat, causing the motor end cover temperature to rise.

External heat dissipation failure is an important contributing factor to overheating, which is closely related to the operating environment of industrial scenarios. First, blocked heat dissipation structures. In dusty scenarios such as textile mills and flour mills, the motor heat sinks and fan covers are easily covered by fibers and dust, blocking heat dissipation channels; in humid environments, water vapor tends to condense on the surface of heat sinks, accelerating dust adhesion and doubly hindering heat dissipation. Second, excessive ambient temperature. In high-temperature scenarios such as steel plants and metallurgical workshops, the ambient temperature can reach above 40°C, exceeding the motor’s designed maximum ambient temperature (usually 35°C), reducing the temperature difference for heat dissipation and significantly lowering heat dissipation efficiency. Third, cooling system failures. For forced air cooling and water cooling systems commonly used in large AC motors, fan damage, water pump failures, or blocked cooling pipelines will directly lead to the loss of heat dissipation capacity and cause rapid temperature rise. In addition, overloaded operation is a common human factor leading to overheating in industrial scenarios. When the motor load exceeds the rated power by more than 15%, the winding current increases significantly, and the copper loss increases in proportion to the square of the current, which can cause overheating in a short time.

2. Targeted Protection and Solutions in Industrial Scenarios

2.1 Prevention: Lay a Foundation for Safe Operation

In response to the above causes, industrial scenarios need to build a protection system from three dimensions: “prevention – monitoring – emergency response”. At the prevention level, first, optimize motor selection. Select a motor with appropriate power according to load characteristics to avoid “a small horse pulling a big cart”. At the same time, choose special motors for specific scenarios—totally enclosed self-cooled motors (with protection class IP55 or above) for dusty environments, and motors with high-temperature resistant insulation classes (such as Class F and Class H, with tolerance temperatures of 155°C and 180°C respectively) for high-temperature environments. Second, strengthen installation and maintenance. Ensure the motor is fixed horizontally during installation to avoid rotor imbalance; clean dust and debris from heat sinks and fan covers regularly (at least once a month), perform lubrication and maintenance on bearings annually, and promptly replace aging winding insulation layers and worn bearings. For terminal connections, use a torque wrench to fasten them according to standards to prevent excessive contact resistance.

2.2 Monitoring: Detect Hidden Dangers in Advance

At the monitoring level, a real-time temperature monitoring system needs to be established to detect overheating hazards early. For small and medium-sized motors, PT100 platinum resistance temperature sensors can be embedded in the stator windings to directly monitor the winding temperature; for large motors, infrared thermometers can be used for regular inspections of key parts such as bearings and end covers, or online temperature measurement devices can be installed to transmit temperature data to the central control system in real time. When the temperature exceeds the threshold (e.g., 140°C for Class F motors), an audible and visual alarm is automatically triggered. At the same time, monitor current and voltage parameters through an intelligent motor controller. When the current exceeds the rated value by 10%, the load is automatically reduced or the motor is shut down to avoid heat generation from overloading at the source. In addition, optimize the design of the heat dissipation system: install independent cooling fans or water-cooled jackets for motors in high-temperature scenarios; adopt a “positive pressure ventilation” method in dusty scenarios, where clean compressed air is introduced into the motor to prevent dust from entering the heat dissipation structure.

2.3 Emergency Handling and Long-Term Optimization: Ensure Continuous Operation

At the emergency handling and long-term optimization level, when the motor issues an overheating alarm, it is necessary to stop the machine immediately for inspection. Use a multimeter to test the winding insulation resistance to determine if there is a short circuit; use a vibration detector to check for bearing wear and rotor balance to avoid expanding the fault. In the long run, establish a full-life cycle management file for the motor, record each maintenance and temperature measurement data, analyze the overheating pattern, and formulate a replacement plan in advance for parts with frequent faults. At the same time, combine energy-saving transformation by replacing old motors with high-efficiency energy-saving AC motors. These motors adopt optimized winding and core designs, which can reduce copper loss and iron loss by 20%-30%, fundamentally reducing heat generation. In summary, the overheating protection of AC motors needs to combine scenario characteristics, and through systematic measures such as “precision selection, enhanced monitoring, optimized heat dissipation, and standardized operation and maintenance”, achieve the dual goals of fault prevention and efficient operation, and ensure the continuity and stability of industrial production.